Introduction

Effective thermal management is crucial in maintaining electronic devices’ and industrial systems’ performance and longevity. Heat sinks and cold plates are two of the most commonly used cooling solutions. Understanding the differences between these options can help you make an informed decision when purchasing from a cold plate manufacturer or heatsink supplier.

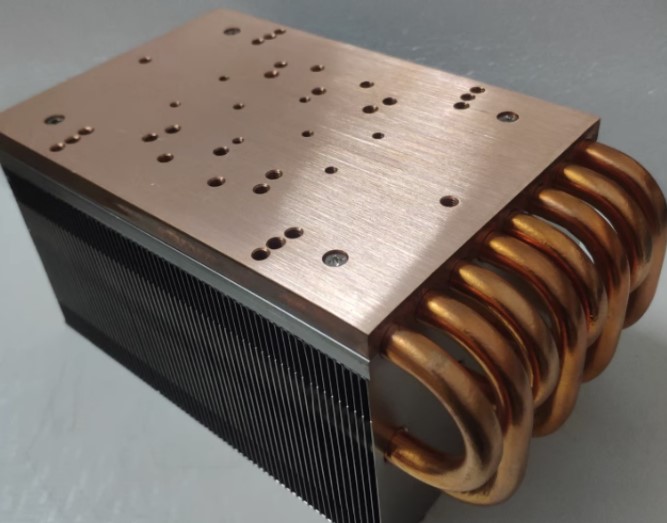

Understanding Heatsinks

Definition and Basic Function

A heatsink is a passive heat exchanger that transfers the heat generated by an electronic or mechanical device to a fluid medium, often air or a liquid coolant. The primary function of a heatsink is to dissipate heat through conduction and convection, thereby preventing the device from overheating.

Types of Heatsinks

Heatsinks come in various types, each designed to optimize thermal performance in specific applications:

- Passive Heatsinks: These rely solely on natural convection and typically have fins or pins to increase surface area.

- Active Heatsinks include a fan or blower to enhance heat dissipation through forced convection.

Materials Used

The performance of a heatsink dramatically depends on the material used:

| Material | Thermal Conductivity (W/m·K) | Advantages | Disadvantages |

| Aluminum | 205 | Lightweight, cost-effective | Lower thermal conductivity than copper |

| Copper | 385 | Superior thermal conductivity | Heavier, more expensive |

Applications

Heatsinks are widely used in various applications such as:

- Electronics: Cooling CPUs, GPUs, and other components.

- LED Lighting: Managing heat in high-power LED fixtures.

- Power Electronics: Dissipating heat in power supplies and inverters.

Understanding Cold Plates

Definition and Basic Function

A cold plate is a device that uses a liquid coolant to absorb and remove heat from a heat-generating component. Unlike heatsinks, cold plates employ conduction for heat transfer from the element to the plate using a liquid to carry the heat away.

Types of Cold Plates

Cold plates can be categorized based on their construction and cooling mechanism:

- Tubed Cold Plates: Feature serpentine or embedded tubing through which coolant flows.

- Brazed Cold Plates: Constructed by brazing multiple metal layers together, creating internal channels for the coolant.

- Friction Stir Welded Cold Plates: Utilize friction stir welding to join metal layers, allowing precise control over the cooling channels.

Materials Used

Cold plates are typically made from materials with high thermal conductivity:

| Material | Thermal Conductivity (W/m·K) | Advantages | Disadvantages |

| Aluminum | 205 | Lightweight, corrosion-resistant | Lower thermal conductivity than copper |

| Copper | 385 | Excellent thermal conductivity | Heavier, more expensive |

Applications

Cold plates are essential in applications requiring efficient thermal management for high-power components:

- High-Power Electronics: Cooling power transistors, IGBTs, and other high-power devices.

- Laser Systems: Managing heat in high-power laser diodes.

- Medical Equipment: Ensuring stable operation of imaging and diagnostic devices.

Critical Differences Between Heatsinks and Cold Plates

Cooling Mechanism

The primary difference between heatsinks and cold plates lies in their cooling mechanisms. Heatsinks rely on air cooling, using fins or pins to dissipate heat through convection. In contrast, cold plates utilize liquid cooling, where a coolant absorbs heat from the plate and carries it away.

Thermal Performance

Cold plates generally offer superior thermal performance compared to heatsinks. The liquid cooling mechanism can remove heat more efficiently, making cold plates suitable for high-power applications. In contrast, heatsinks are adequate for lower-power applications where air cooling is sufficient.

Design and Complexity

Heatsinks are more straightforward in design and more accessible to manufacture. They typically consist of a solid metal block with fins or pins to increase surface area. Cold plates, however, are more complex. They require intricate designs to create internal channels for the coolant and may involve advanced manufacturing techniques such as brazing or friction stir welding.

Installation and Maintenance

Heatsinks are relatively easy to install and require minimal maintenance. They are passive components that, once installed, typically do not need further attention. Cold plates, however, involve a more complex installation process. They require a pump, tubing, and a coolant reservoir, and they need regular maintenance to ensure the coolant remains effective and the system is free from leaks or blockages.

Cost Considerations

Cost is a significant factor when choosing between a heatsink and a cold plate. Heatsinks are generally more cost-effective due to their straightforward design and manufacturing process. While more expensive, cold plates offer better performance for high-power applications, which can justify the higher initial investment and ongoing maintenance costs.

Choosing the Right Solution for Your Needs

Factors to Consider

When deciding between a heatsink and a cold plate, several factors should be considered:

- Heat Load Requirements: A heatsink may suffice for low to moderate heat loads. For high-power applications, a cold plate may be necessary.

- Space and Weight Constraints: Heatsinks are typically lighter and require less space than cold plates.

- Environmental Conditions: Cold plates can provide more efficient cooling in environments with limited airflow.

- Budget and Cost-Effectiveness: Heatsinks are more affordable, but cold plates offer superior performance for critical applications.

Industry-Specific Recommendations

Different industries have specific cooling needs. Here are some recommendations:

- Data Centers: Cold plates are ideal for cooling high-density server racks with significant heat loads.

- Automotive: Heatsinks can be used for general electronic cooling, while cold plates are suitable for cooling electric vehicle power electronics.

- Medical Devices: Cold plates ensure precise temperature control for sensitive imaging and diagnostic equipment.

Future Trends in Thermal Management

The field of thermal management is continuously evolving. Emerging technologies and materials are driving advancements in both heatsinks and cold plates:

- Advanced Materials: New materials with higher thermal conductivity are being developed.

- Microchannel Cold Plates: These offer even more efficient cooling by increasing the surface area in contact with the coolant.

- Hybrid Solutions: Combining the benefits of both heatsinks and cold plates for optimal performance.

Conclusion

In summary, choosing between a heatsink and a cold plate depends on your specific cooling needs, budget, and application requirements. Heatsinks are cost-effective and straightforward, making them suitable for low to moderate heat loads. More expensive and complex cold plates provide superior cooling performance for high-power applications. By understanding the differences and considering the factors outlined, you can make an informed decision when purchasing from a cold plate supplier or a heatsink manufacturer.