The technology of Vapor Chamber soaking plate is similar to that of heat pipe in principle, but different in conduction mode. The heat pipe is one-dimensional linear heat conduction, while the heat in the vacuum cavity soaking plate is conducted on a two-dimensional surface, so the efficiency is higher.

The liquid at the bottom of the vacuum chamber absorbs the heat of the chip, evaporates and diffuses into the vacuum chamber, conducts the heat to the cooling fin, and then condenses into the liquid back to the bottom. It circulates quickly in the vacuum chamber and achieves quite high heat dissipation efficiency.

Coolant (purified water or refrigerant) is heated in vacuum ultra-low pressure environment and quickly evaporates into hot air (< 104 Tor or less)– heat absorption .Vapor Chamber adopts vacuum design, hot air flows more quickly in copper mesh micro-environment – heat conduction . The hot air rises when heated, dissipates heat when it meets the cold source on the upper part of the heat dissipation plate, and recondenses into liquid heat dissipation . The condensed coolant flows back into the evaporation source at the bottom of the spillage plate through the capillary channel of the copper microstructure. The returned coolant is heated through the evaporator and then vaporized again and absorbs heat through the copper microtubule. Heat conduction,Heat dissipation, so repeated action.So As a new type of two-phase flow heat technology, uniform temperature plate has the advantages of high thermal conductivity, good temperature uniformity, reversible heat flow direction and so on. It has overcome the traditional heat pipe small contact area, large thermal resistance, uneven heat flux and other problems, and has become one of the effective ways to solve the future high heat flux electronic device heat dissipation in the electronics industry

What are the characteristics of the Vapor Chamber ?

1,Strong thermal conductivity: thermal conductivity up to 3000 ~ 10000W/(mK);

2,Large heat dissipation power: by changing the heat dissipation area, change the heat dissipation problem of local large heat flux;

3,Good temperature performance: temperature difference is less than 2-3℃;

4,Strong structural adaptation: the shape is not restricted, can be square, round, etc., to adapt to a variety of heat dissipation environment;

5,Usually,C1100 material is used for production, and the sintered capillary structure is copper powder

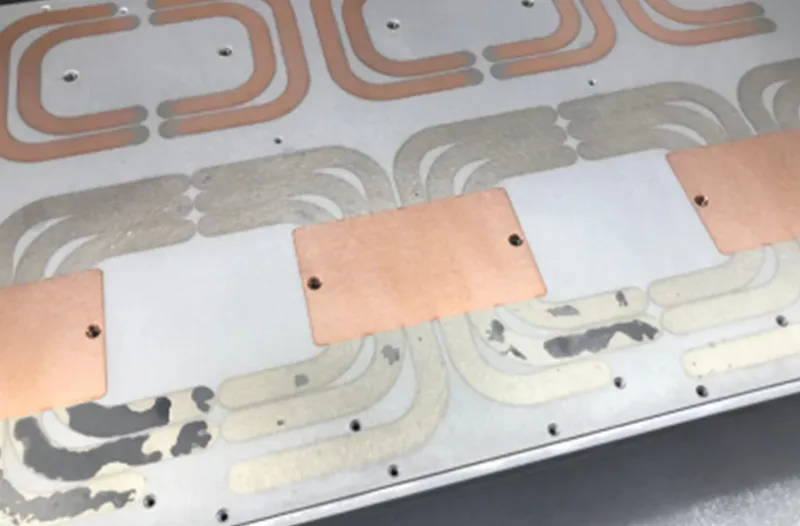

These products that we have produced