Tunnel Series Platform Product Solution

We will use professional thermal analysis software to design the optimal scheme for customers, then confirm the

feasibility of the theory with engineers, and then start to make samples for testing

Tunnel Series Platform Product Solution

Project Details

Customer:

Medical Diagnostic systems

Application:

Medical equipmentindustry

Technology:

Liquid cold plate

Thermal power type:

TEC cooling

Location:

UK

Intruduction

Medical Diagnostic systems

To maintain control the Temp 4℃ to 6 ℃ of the reagents from ambient temp 23℃ to 30℃.

Old Tunnel Series Product List

-2 for AA

- 6 for DA

Old Tunnel Series product line

-Lower cooling capacities

-Some units CoP < 70%

New Goal for Tunnel Series product

-Align with cooling capacities

-expand higher capacities

The Thermal Solution

Designed requirements

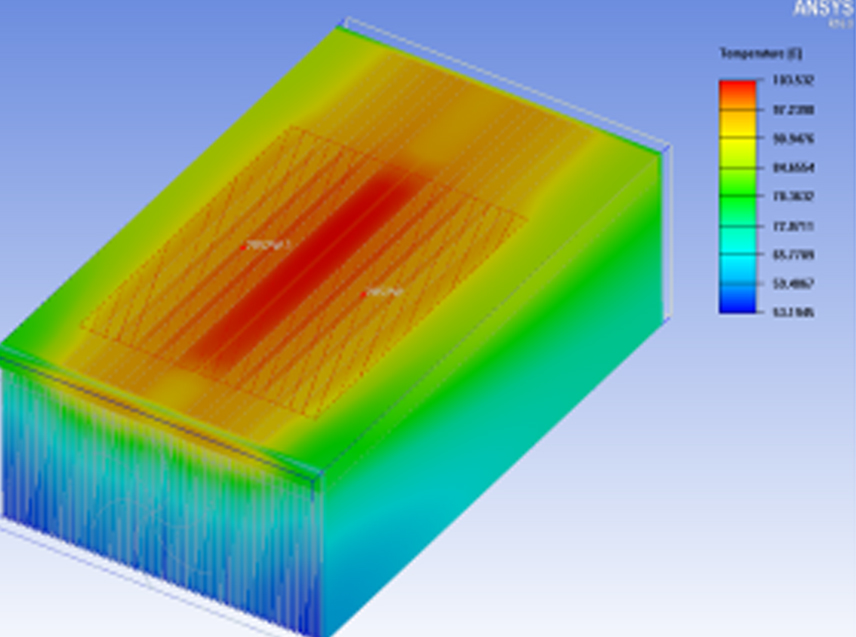

Simplified model and heat source in FloTHERM

Design process

Extrusion profile Design

Extrusion tooling constraint

Series consideration, same profile / difference fan

Cooler design for both sides

Fine tune heat sink fin size during simulation

Pick up TEM module

Input thermal resistance to select best TEM

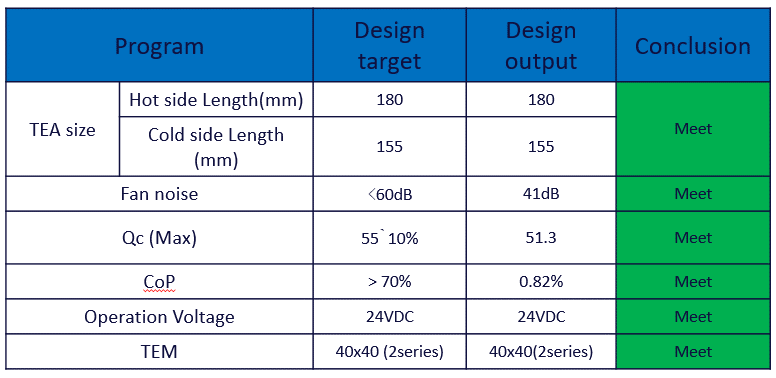

TEA design output

Design target / Mechanical design / sampling & testing

Extrusion profile Design

Extrusion Fin Design

-The Fin Ratio ≤22:1

-The Fin Thick ≥0.7mm

- Fan Gap = 0.446(L²/ΔP) (unit: mm, Pa)

Extrusion profile Design output

Width & Height : 66*60mm

Base thick: 7mm

Fin Thick: 1mm

Fin Gap: 2.7mm

Fin height: 57mm

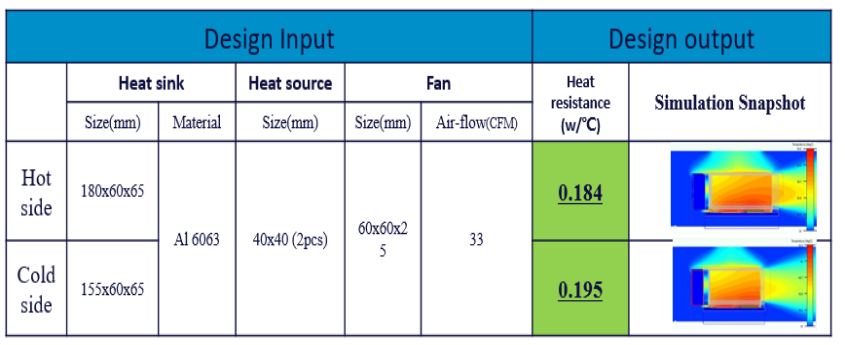

Cooler design for both sides,Conclusion:

Per the simulation, the hot side heat sink resistance is 0.184, and cold side is 0.195

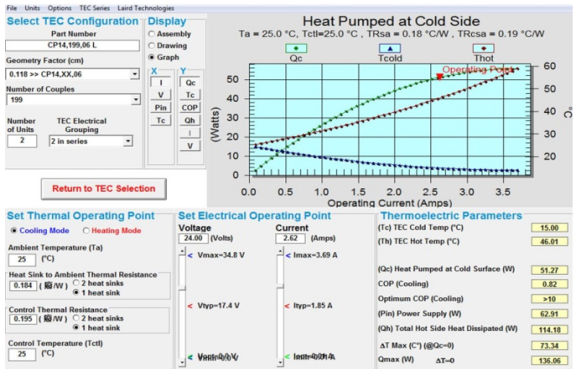

Pick up TEM Module

Conditions for TEM

Hot side resistance: 0.184

Cold side resistance: 0.195

Ambient Temp 25℃

Qc Max: 50w

CoP ≥0.7

Pick up the TEM module

-CP14.199.06

TEA design output

Results

From the perspective of this structure, the designed parameters can fully meet the customer's requirements. Generally speaking, we will ask the sample engineer to start making samples based on these data