TEC Cooling Solutions

The TEC is a high performance small thermoelectric cooler. This thermoelectric material improves cooling performance on the basis of standard products. Ensures repeatability and long life operation in temperature-stabilized applications of optoelectronic devices used in the telecommunications and industrial laser markets.

TEC cooling solutions.Our professional design and production of thermoelectric cooler, can achieve cooling below the ambient temperature ability, at the same time we can also solve the problem of condensate water refrigeration, to provide customers with accurate temperature control and refrigeration effect, usually used in medical equipment, process precision machinery, telecommunications equipment, etc.

Thermoelectric cooler,which is a kind of cooling device composed of semiconductor, with the development of modern semiconductor has practical application, that is, the invention of refrigerator. Its working principle is the DC power supply to provide the energy required by the electron flow, through the power supply, the electron negative electrode (-) starting, first through the P-type semiconductor, in this heat absorption, to the N-type semiconductor, and the heat will be released, each after a NP module, there is heat from one side is sent to the outside side caused by the temperature difference and the formation of hot and cold end. The hot and cold ends are respectively composed of two pieces of ceramic, and the cold end is connected to the heat source, which is to cool it. In the past, the refrigerator is used in the CPU. It uses the cold end face to cool the CPU, and the heat from the hot end face must be discharged by the fan. Refrigerators are also used to make cold/hot car incubators. The cold side can cool drink machines, and the hot side can keep hot things warm.

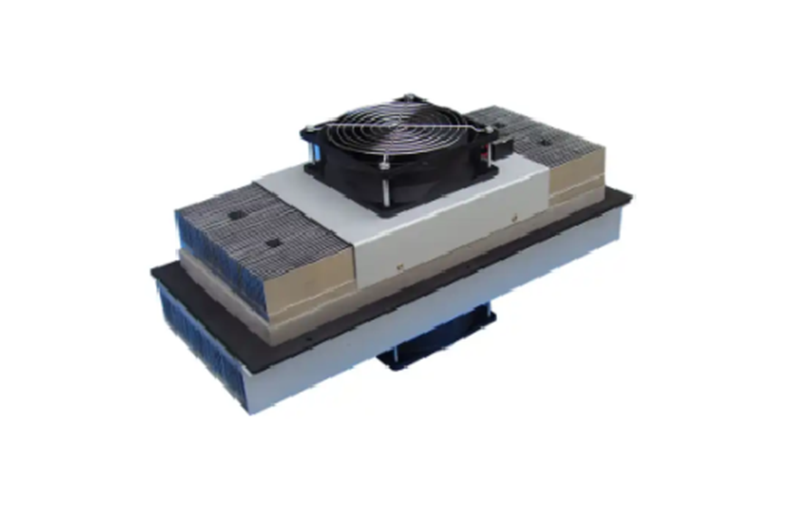

Peltier Air Conditioners

Thermal management for electronic cabinets and kiosks

Peltier air conditioners offer dependable, compact performance by cooling objects via convection. They are commonly used in sample storage chambers for medical and analytical instrumentation, electronic enclosures, and compartment storage for food and beverage applications.

Heat inside the chamber is absorbed by the cold side heat exchanger. The thermoelectric coolers pump heat from the cold side heat exchanger and dissipate through the hot side heat exchanger to the outside environment. The internal air circulation from the cold side fan helps minimize temperature gradient within the enclosure.

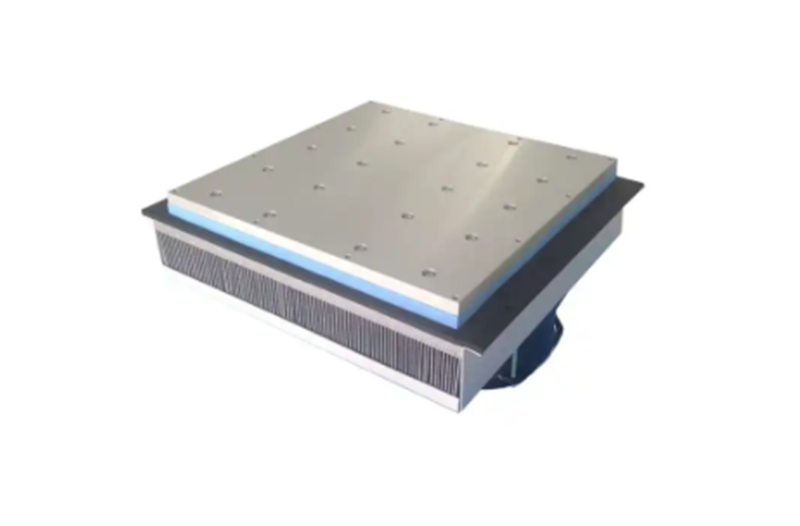

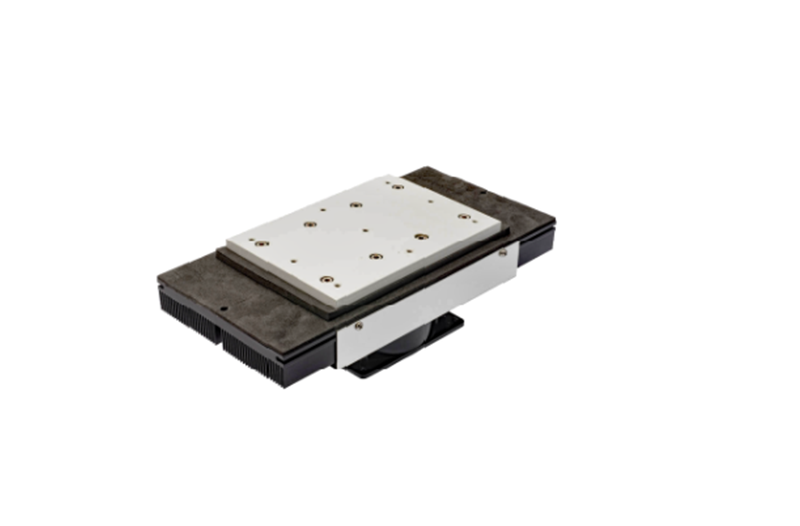

Peltier Plate Assemblies

Peltier plate assemblies provide reliable, compact performance by conducting cooling objects. This configuration is suitable for smaller sample storage rooms for medical and analytical instruments, spot cooling of laser systems or sensitive optical electronics for industrial and telecommunications markets. The heat is absorbed through the cold plate and the thermoelectric cooler pumps the heat into the surrounding environment through the hot side heat exchanger. An internal cold plate makes the chamber completely sealed, which helps contain biohazardous liquids and minimizes contamination. It also saves the chamber space that cannot accommodate the cold side heat exchanger.

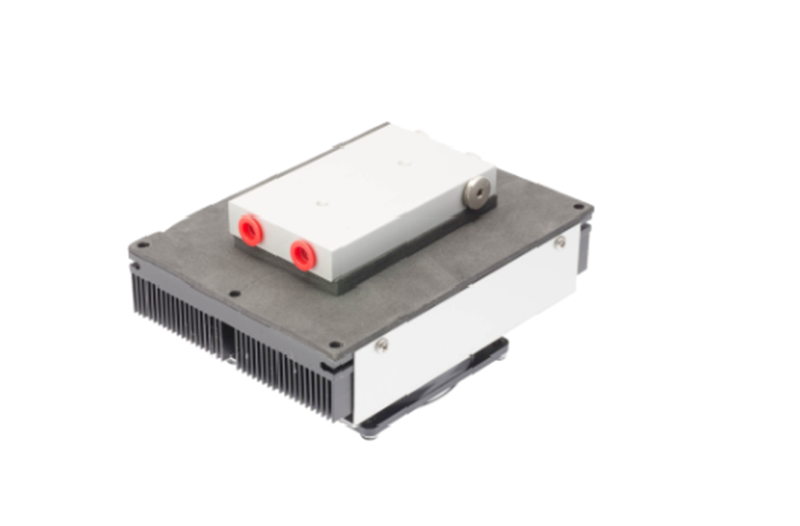

Liquid Series

The liquid series thermoelectric cooler assembly is used to cool or heat the coolant flowing through the liquid heat exchanger. The heat exchanger is designed for circulatory cooling system applications that require a pump and associated piping to complete the liquid loop. The heat is absorbed by a heat exchanger on the cooling side and a custom-designed thermoelectric cooler pumps the heat to a matching heat exchanger on the cooling side. The heat dissipation side can be convection (liquid to air), conduction, (direct to liquid) or through liquid (liquid to liquid). To improve heat transfer

Considerations in design and use of Peltier

1,One side of the cooling plate is installed with the heat sink, one side is installed with the cooling guide system, the flatness of the installation surface is not more than 0.03mm, to remove burrs and dirt.

2,The cooling plate is in good contact with the heat sink and the cooling guide block. The contact surface must be coated with a thin layer of thermal grease.

3,When fixing the refrigeration plate, the force of the refrigeration plate should be uniform, and attention should be paid not to excessive, in order to prevent ceramic fracturing.

4,The DC power supply voltage must not exceed the rated voltage, and the ripple coefficient of the power supply is less than 10%.

5,The current shall not exceed the rated current of the component.

6,the refrigeration sheet is working shall not instantaneously through the reverse voltage (after 5 minutes.

7. The inside of the refrigeration sheet shall not be flooded.

8, the humidity around the refrigeration sheet shall not exceed 80%

Standard specification dimensions are as follows:

(Length X Width X HighX Qcmax XTmaxXVopXPower)

80x60x79mm x24w x42 x12v x29w

80x60x79mm x24w x42 x12v x34w

160x122x91mm x43w x42Cx12v x73w

160x122x91mm x47w x42Cx24v x60w