Case Study For A Liquid Cold Plate Thermal Design

To use professional thermal analysis software to design a liquid cold plate schemes for customers, then confirm the feasibility of the theory with engineers, and then start to make samples for testing.Share successful design experiences with us for research and learning.Of course, these cases are some of our own project research, and the final design solution is owned by the customers.

Thermal analysis of liquid cooling plate for 280AH-104S battery module

Project details:

Our thermal management project is used for the thermal management of battery cells and is also our standard product. The intellectual property rights belong to our company, so many important parameters can be shared. The theoretical design of this standard product is compiled and applied in practice, which is in line with the common battery module requirements of many customers in the market.

The entire cold plate is produced using extrusion technology, and the inlet and outlet of the cold plate are welded using friction stir welding technology.The length of the cold plate can be customized according to customer needs, and the width is fixed and cannot be changed.

The designed requirements

Cooling method: liquid cooling

Cooling medium: 50% (volume ratio) ethylene glycol aqueous solution

Inlet temperature: 18 ℃

Cooling fluid flow rate: 6.25LPM;

Number of battery cells: 52 pcs

Heating power of a single battery cell: 12 W

Total dissipated power of battery cells: 624 W

Remarks: Channel height 5.0mm, Pitch 22mm, with raised pointsS-shaped channel

Target requirements:Liquid cooled plate temperature rise Delt T ≤ 3 ℃

Pressure drop at inlet and outlet ≤ 11.25 Kpa

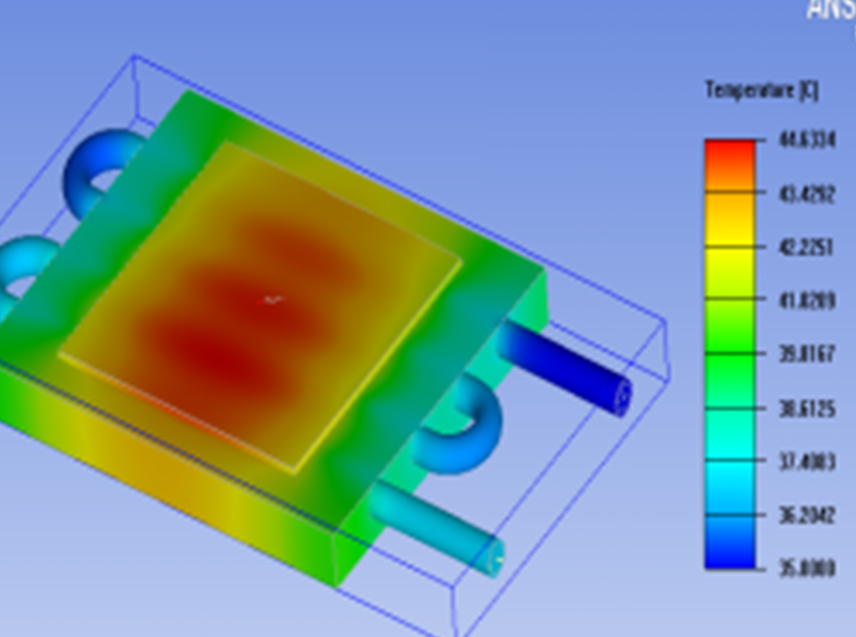

The thermal solution of the temperature

After setting parameters and running calculations, the temperature distribution of the entire liquid cooling plate is obtained. The highest temperature of the battery cells is around 25 degrees, and the temperature of the entire module is relatively uniform. The surface temperature of the liquid cooling plate is between 18 and 20 degrees, which is also very uniform. In theory, it is suitable for the normal operation of the battery module cells, and the temperature difference is small.

Flow rate and pressure drop in thermal analysis

Based on theoretical calculations, we can see that when the flow rate of the entire cold plate is 6.25L/min, the maximum flow rate in the flow channel is 0.24m/s. The velocity in the entire flow channel is uniform and no vortices are formed, which is conducive to the conduction of coolant and heat. At the same time, it is also concluded that this concave convex feature in the flow channel of the liquid cold plate can achieve fluid turbulence, maximize heat exchange, and take away a large amount of heat, achieving the purpose of our design.

The calculations:

we can see that when the flow rate of the entire cold plate is 6.25L/min, the maximum flow rate in the flow channel is 0.24m/s. The velocity in the entire flow channel is uniform and no vortices are formed, which is conducive to the conduction of coolant and heat. At the same time, it is also concluded that this concave convex feature in the flow channel of the liquid cold plate can achieve fluid turbulence, maximize heat exchange, and take away a large amount of heat, achieving the purpose of our design.