Inverter-Thermal Solution Design

We will use professional thermal analysis software to design the optimal scheme for customers, then confirm the feasibility of the theory with engineers, and then start to make samples for testing

Thermal analysis of liquid cooled plate of 700W inverter

Project Details

Customer:

Automobile braking driving

Application:

Automatic control system

Technology:

Liquid cold plate

Thermal power type:

700W

Location:

USA

Intruduction

The space required for an automatic hole control system is very small. Often, a very limited amount of space is needed to solve complex electronic control systems. Today, we will discuss the design of a liquid cooling plate for an automotive automatic control system. The customer has selected an inverter with 600W thermal power, which can reach up to 700W when running. Therefore, we need to ensure that the temperature stays within 65 degrees Celsius at all times for safety reasons.

The Thermal Solution

Designed requirements

1, The single inverter module should be rated at 250W with a peak of 350W; Total thermal power is 350*2=700W;

2, In the automotive industry, control the inverter temperature of the electronic control box withina range of 65 degrees.

3,Determine that the flow rate of the entire system through the inverter must not be less than 7L/minute.

4, Taking into account the safety standards of electronic components, the waterproof structure of the cold plate box and other factors, my engineer adjusted the size of the cold plate box. The final size is 266x224x74.5mm; Based on cost considerations, we recommend using the die-casting process and friction stir welding process

5,Inlet water Tem 45 ℃

6,Environment 45℃

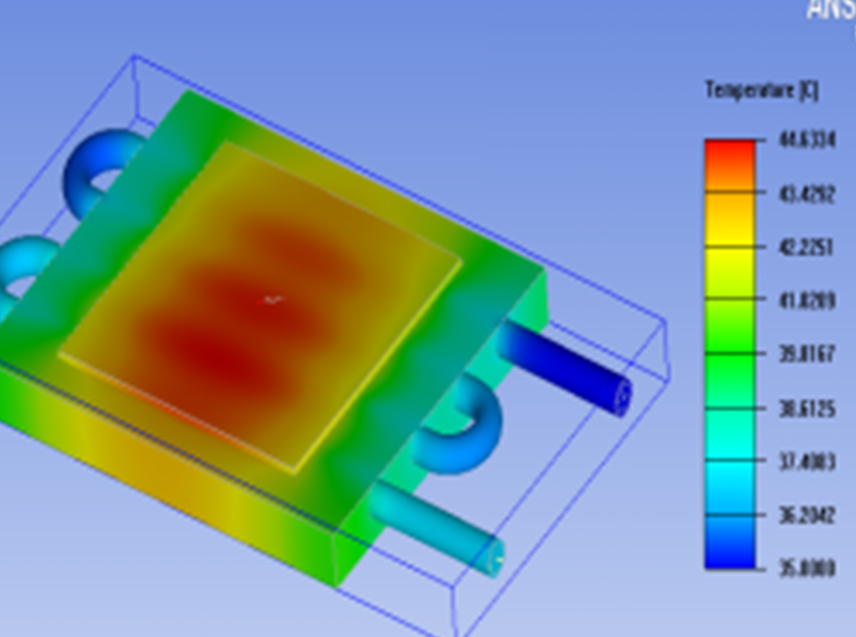

Simplified model and heat source in the Ansys software

Parameter setting and meshing are in the software

Ambient temperature 45 ℃

Thermal radiation is not considered

Turbulent flow regime

Operating pressure 101325N/m2 on Natural convection

To solve the function calculation equation, make each curve function equation convergent based on the set parameters and Grid setting partition

The number of meshes is 495341

Set uniform mesh params

Mesh assemblies separately

Allow multi-level meshing

Allow minimum gap changes

After calculation, the temperature distribution cloud map of the whole liquid cooling plate is obtained, and it can be seen that the highest temperature is 65.81 degrees

Orient positive X,Y,Z Temperature

Water pressure distribution and Water Speed distribution

Results

After calculating this module, our engineers found that the customer's requirements can be met with existing size data. However, actual sample test data should be conducted after processing. Theoretically, there may be differences between the actual sample test data and simulation analysis due to simplified data in the module, but these differences will not be significant. We often design with a 5% margin.