3700W heat sink thermal solution

We will use professional thermal analysis software to design the optimal scheme for customers, then confirm the feasibility of the theory with engineers, and then start to make samples for testing

Project Details

Customer:

Automatic control manufacturer

Application:

Automatic control industry

Technology:

FSW process

Thermal power type:

IGBT cooling

Location:

Italy

Intruduction

Our engineers analyzed the customer's demand when they got it. Since the power is 3700W, forced convection must be adopted, and two suitable fans should be selected. Since the customer's space size is relatively small, the fans must have high efficiency and large air volume. At the same time, the heating source is the 3700W IGBT where the heat is concentrated, so the heat pipe with high efficiency must be used for local heat distribution and diffusion and heat removal.

The Thermal Solution

Designed requirements

• Mode:Power 4*688W+3*305W=3667W;

• Input flow 512.8CFM/1.1In_water

• Environment 45℃

• The Max temperature of heat sink surface is below 103.9 ℃

• The temperature difference of the same chip type is about 2 ℃

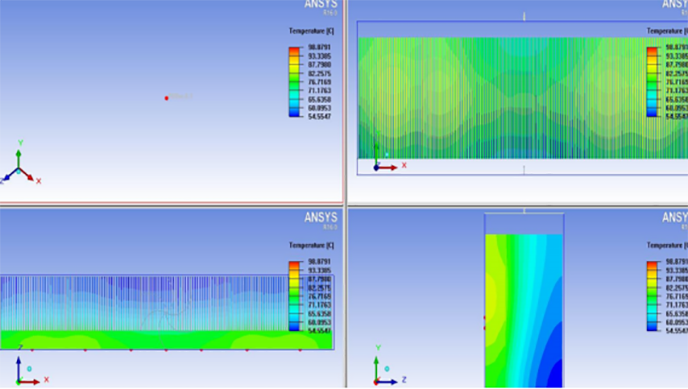

Simplified model and heat source in the Ansys software

Parameter setting and meshing are in the software

To solve the function calculation equation, make each curve function equation convergent based on the set parameters

After the software is run, the air volume pressure is obtained, so as to determine a reference value for the fan resistance impedance in the later period

Also, after the software is run, the speed of the air volume is obtained, so as to determine a reference value for the later fan air volume

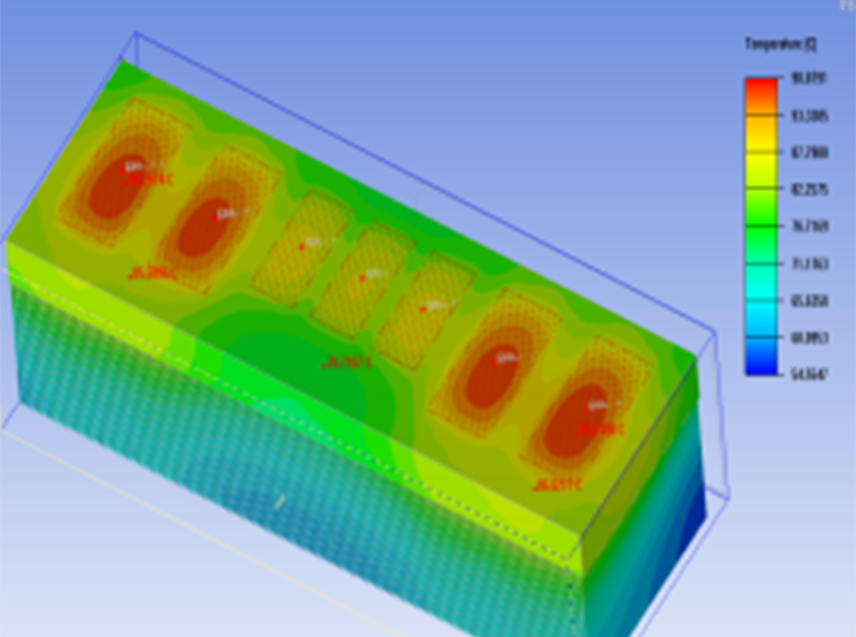

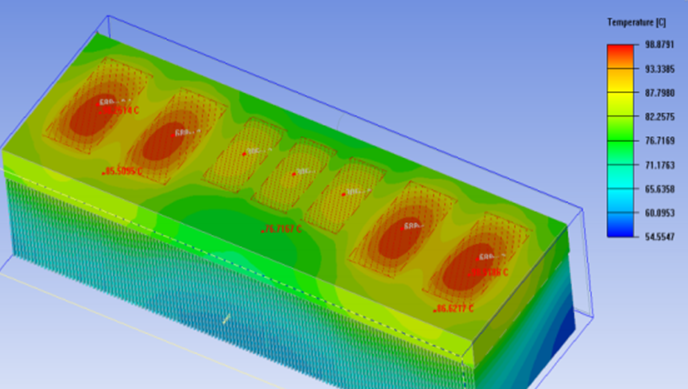

After calculation, the temperature distribution diagram of the heat source within the range of the set module is obtained, and then the engineer can optimize it.

Results

Our engineers use detailed data and accurate meshing CFD software for calculation. By constantly adjusting the data module, heat pipe position, and thickness and spacing of heat sinks fins, we finally designed a heat sink scheme meeting the requirements for the customer. Meanwhile, we have made sample testing and mass production. However, the heat pipe heat sink should be noted that in extreme environment, the liquid inside the heat pipe is easy to freeze and then expand. The location and gravity direction of the main heat pipe are required.Used the simple model method, the result will be different from the actual module.The Max temperature of heat sink surface is below 98.8 ℃,△T=98.8-45=53.8℃ Thermal resistace:53.8/3667=0.0146 ℃/w