The microchannel process of copper skived fin is crucial for its application in the field of heat dissipation.

In liquid cooled plates, the high thermal conductivity of copper combined with microchannel technology greatly improves heat dissipation efficiency. This can ensure normal temperature during high load operation of electronic devices, avoiding performance and lifespan issues caused by overheating. Its good stability and corrosion resistance reduce maintenance costs. And its’ small size and light weight enable it to effectively dissipate heat in scenarios that require high space and weight.

In terms of computer computing servers, the servers operate under high load for a long time, and the core components generate a lot of heat. Copper skived fin heat sink can quickly reduce temperature, and probability of failure caused by high temperature. It can also improve server reliability and stability, and extend service life. For high-performance servers, good heat dissipation also provides the possibility of overclocking.

For graphics card heat sinks, the graphics card generates a lot of heat when running tasks. The copper-skived fin heat sink effectively reduces temperature and avoids lagging, crashes, and other situations, ensuring stable performance under high loads. At the same time, it provides heat dissipation support for graphics card overclocking, helping to improve performance. It has a beautiful appearance and is made of durable material. In summary, copper skived fins have many advantages in these application scenarios, including efficient heat dissipation and stable equipment operation and performance.

Skived fin copper heat sink Manufacturer — Kenfatech

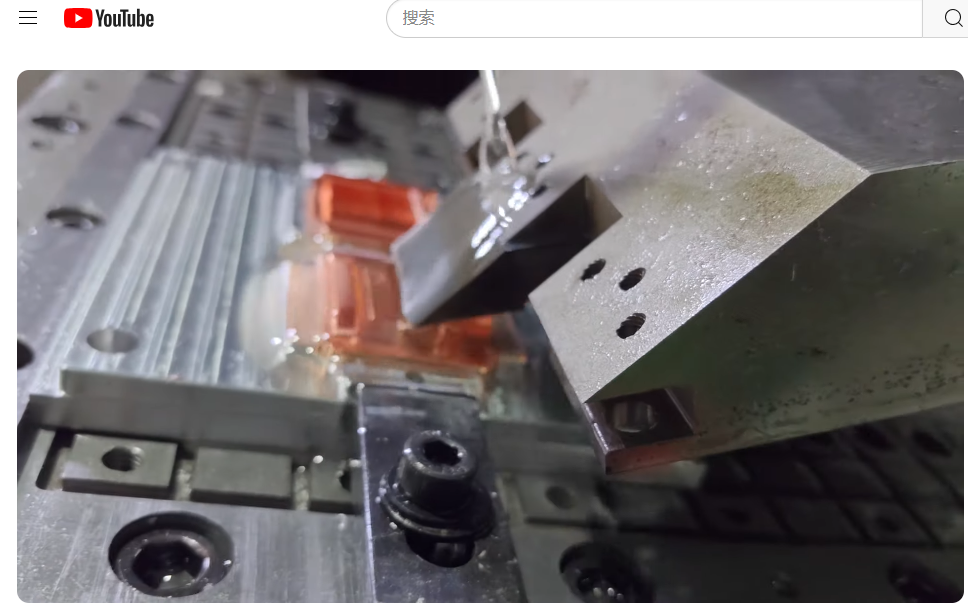

Copper skived fin heat sink we produce is generally used for liquid cooling plates in brazing processes. In current high-power computer operation centers, the heat dissipation of ultra-high-power graphics cards cannot be separated from this copper-skived fin heat sink. We usually use copper C1100 material for annealing.

At this time, the strength of copper needs to be reduced to achieve O-state hardness. In this way, we can process the thickness of the fin to a thickness of 0.05 to 0.1mm. In theory, this copper heat sink can play a very important role in heat exchange in liquid cooling plates. For high-power CPUs in computer centers, which have high power density chips, it can quickly transfer heat and achieve… The guarantee of stable and fast computer operation. We can provide customers with various customized thermal design and production solutions to meet their market needs.