with over 10 years of experience

A reliable production process is the guarantee of quality.

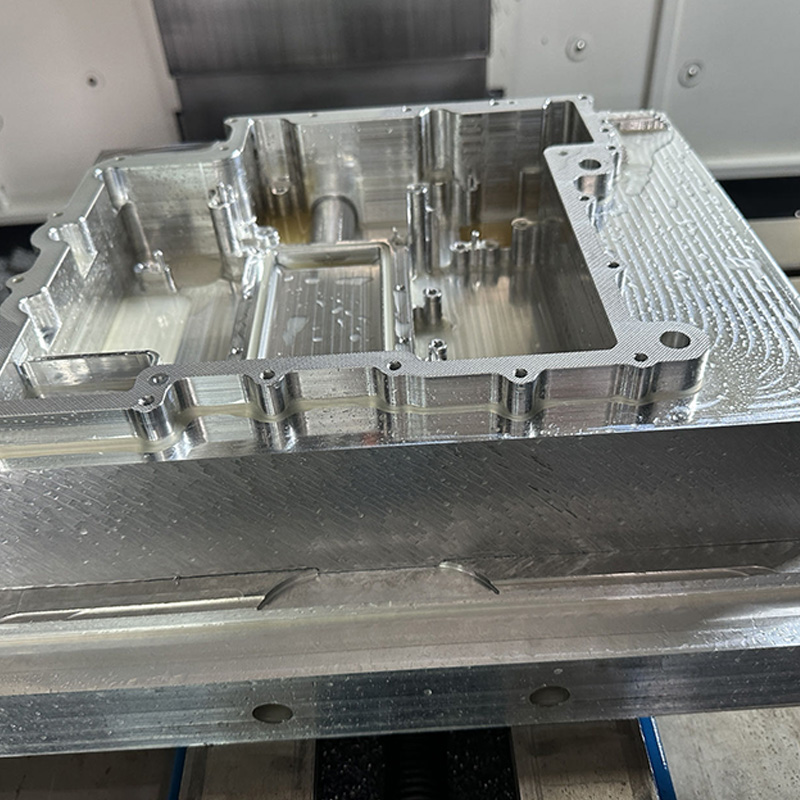

Customized Design And Manufacturing

Customized Design And Manufacturing

Customized Design And Manufacturing

Customized Design And Manufacturing

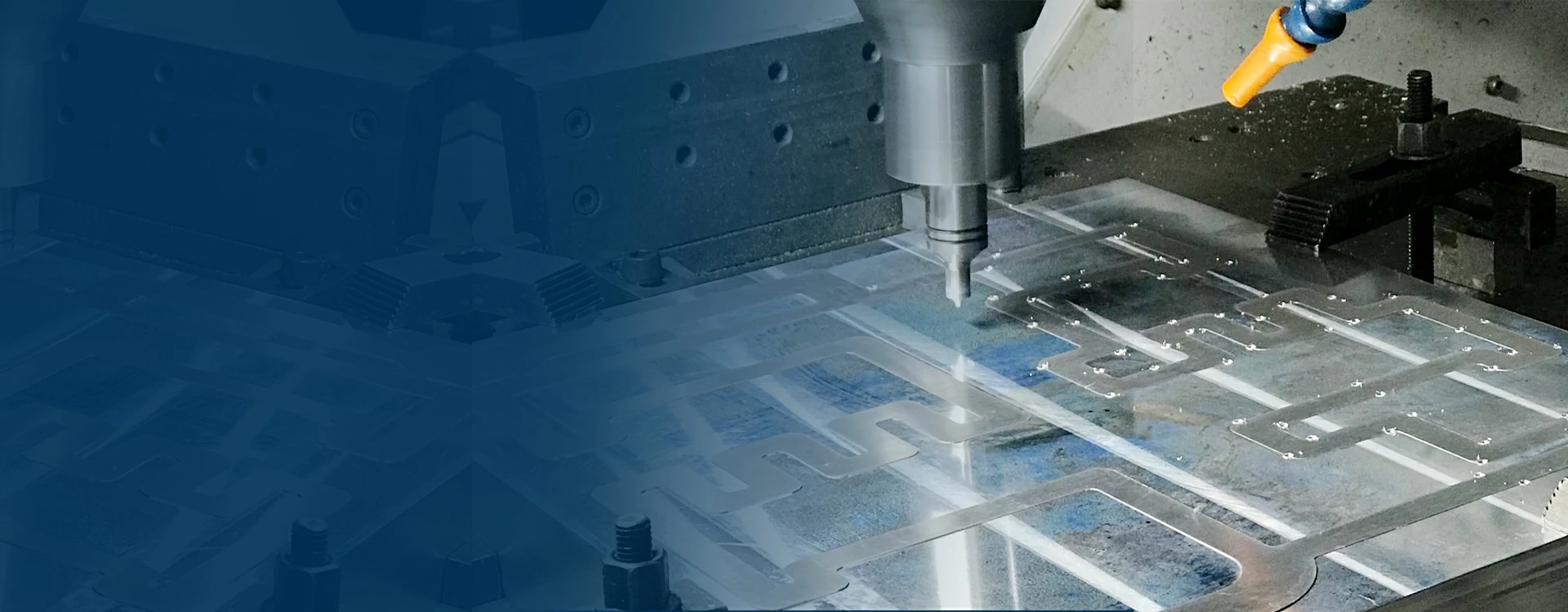

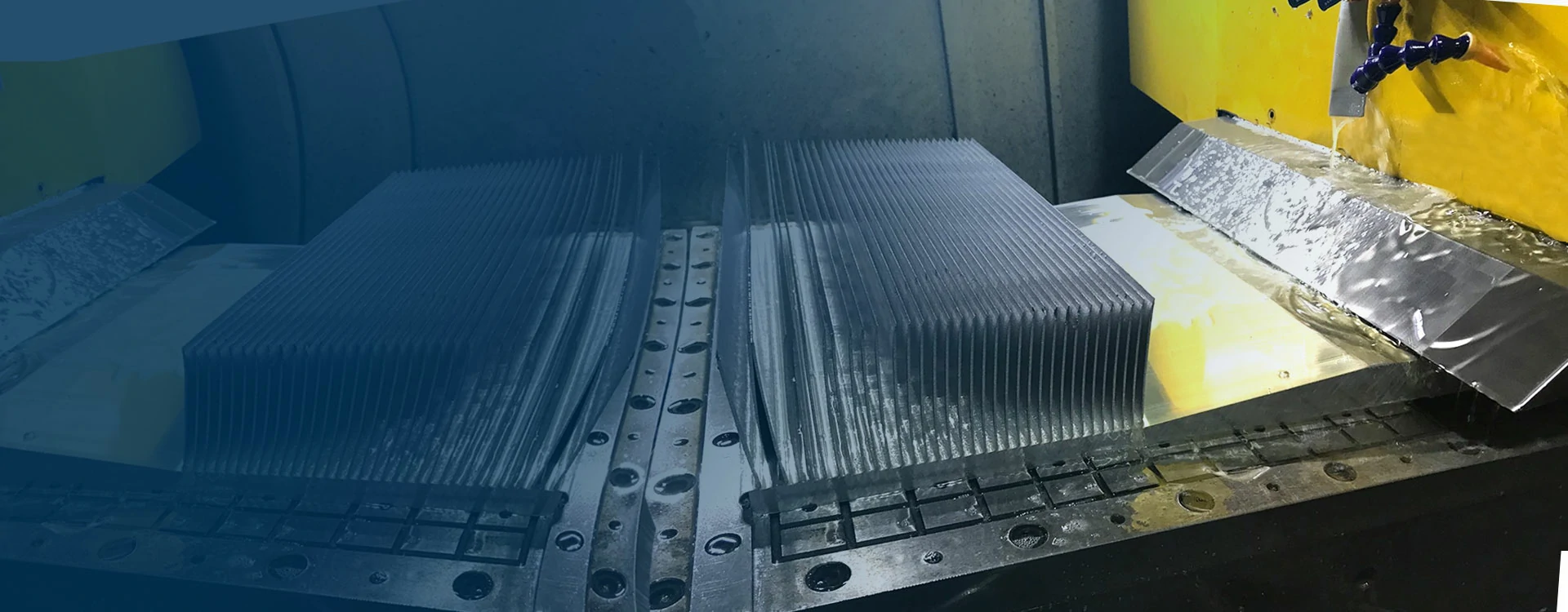

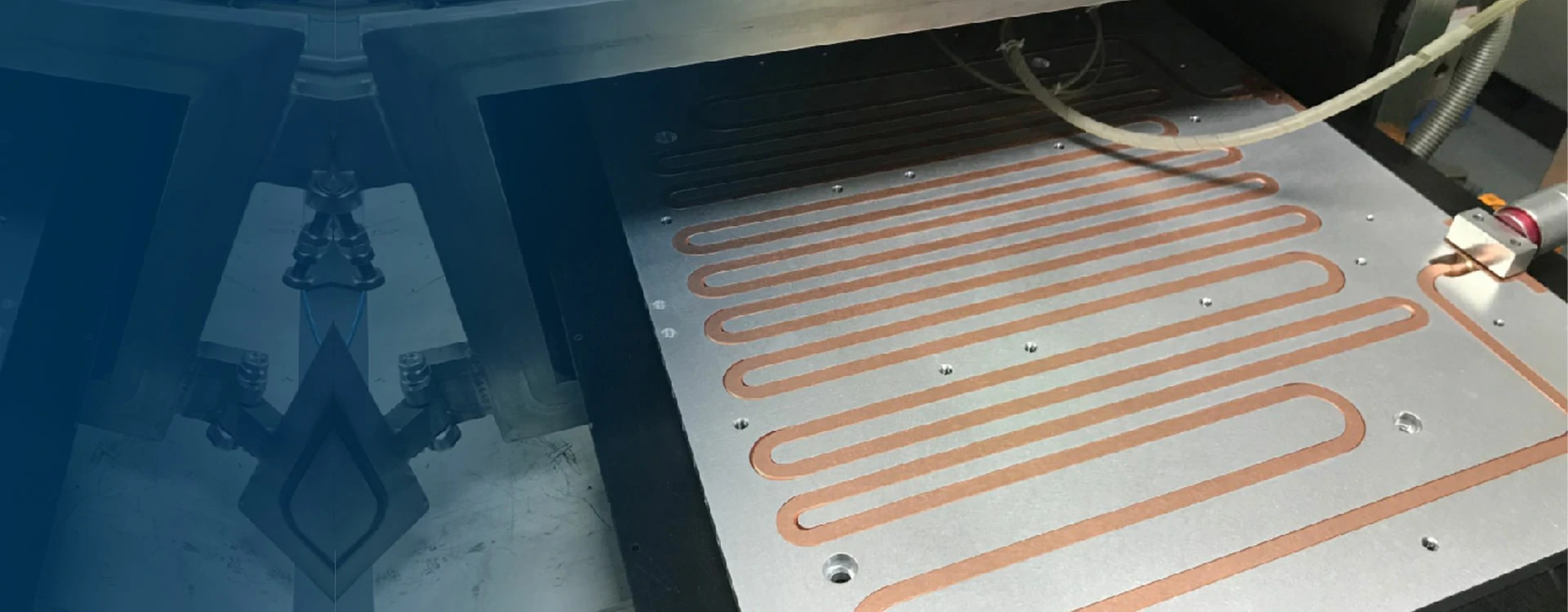

Heat Sink and Liquid Cold Plate Manufacturing Services

Kenfa Tech, a distinguished high – tech enterprise, excels in the comprehensive process of high – power heat sink and liquid cold plate production, including meticulous design, advanced development, rigorous testing, precise optimization, and customized manufacturing. Our team of experts, armed with cutting – edge technology and extensive experience, ensures that each heat sink not only meets but exceeds industry standards. We are dedicated to providing customers with top – quality products of unwavering reliability and the most economically efficient design solutions, making us a leader in the heat sink technology domain.

Kenfa Tech is a total thermal solution design and production company, providing customers with the best cooling solutions for different needs.It is also most cost-effective solution.

Kenfa Tech Industrial Limited, a national high-tech enterprise with over a decade of experience, specializes in heat sinks production. We offer diverse cooling solutions tailored to market demands. Our skilled engineers, formerly with renowned cooling firms like AAVID and Foxconn, ensure precise project control and seamless product development.

Utilizing Ansys Icpak and Flothermal software, we conduct thermal analyses for customer engineers. Our structural engineers optimize production processes following sample testing, delivering cost-effective solutions. Our comprehensive production line includes CNC precision machining, high-power heat sink soldering, skived fin heat dissipation, brazing process, friction stir welding, flow resistance of liquid cold plates and rigorous testing methods. We also provide surface treatments like cleaning, degreasing, and chromate coating. Accredited with ISO9001:2008, ISO14001:2004, and IATS16949 certifications, we assure customers of system-level quality standards.

Our robust capabilities go beyond numbers.

How to serve our customers

With our more than 10 years of production and operation, we can quickly respond to customer needs, streamline and accurately control the entire production cycle of products, at the same time, based on our ERP system, we generally follow four steps to complete

Get the customer's needs

We usually get some heat sinks or cooling system design requirements from our customers

Design or DFM

After receiving the drawings of existing designs, our engineers will conduct a DFM evaluation. In addition, for some customer-oriented conceptual designs, our engineers are required to perform structural design and thermal protection analysis.

Making Samples

After getting the customer's confirmation of the drawing, we will arrange the production of the sample, which usually takes 3-4 weeks to complete according to the customer's payment date

Customer Confirmation

After the customer's test, finally determine whether to meet the requirements

Our advantages

We have more than 10 years in the heat sink production and processing of advantages, R & D design team for customers to do the thermal solution and design programs, quality systems and process specifications.

– OEM/ODM for customers.

– Lead time 3 to 4 weeks.

– ERP system control process.

– ISO9001:2015 Certified Factory

– IATF 16949:2016

– More than 10 years making heat sinks experience.

– Professional thermal analysis software (Icepak,Ansys,Qfin )

– Engineer 1 to 1 project management and technical support.

– Reliable after-sales service

Main Production Manufacturing Equipments

For heat sink production equipment, different process products need different equipment, relatively speaking, high-power products will basically use CNC machine , soldering welding furnace, friction stir welding machine, skived fin machine and so on

Our Latest Blog Posts

Check our latest blog posts, you can know the latest situation of our company, especially the new technology and new technology, can have a certain design inspiration for the customer design engineers

Top 10 Thermally Conductive Materials You Need to Know in 2025

Have you ever wondered why your phone doesn’t overheat when you’re gaming for hours? Or why some metals feel super cold when you touch them? It’s all about thermal conductivity—how fast a material can move heat. In this article, we’re diving into the top 10 materials that are awesome at

Skived Fin Heatsinks: Custom Cooling for High-Density Designs

Introduction High-density electronics are pushing thermal management to its limits—overheating risks, cramped designs, and slow prototyping can derail even the best projects. Engineers and OEMs need cooling that’s precise, efficient, and fast to deploy. Enter the **skived fin heatsink**: a custom solution that maximizes heat dissipation with thin, optimized fins

Bonded Fin Heatsinks: Compact Telecom Cooling Solutions

Introduction Telecom engineers face a tough reality: compact systems generate serious heat, and poor cooling can tank performance or fry equipment. With space at a premium, finding a heatsink that handles high heat loads without hogging room is critical. That’s where bonded fin heatsinks shine. Offering high fin density and

EV Battery Cooling System – How Does It Work?

Car batteries can overheat during charging or high-speed driving. This raises safety concerns and performance risks. Proper temperature control soothes these concerns. It keeps energy flow stable and extends battery lifespan. That assurance helps users trust EV technology and stay confident on the road. An EV battery cooling system works