Today, decarbonization and digitization are pushing power management technology toward new trends. Increasing efficiency, reducing equipment weight, increasing power density, and increasing the range of electric vehicles are all topics of common concern in our daily lives. For a long period of time in the semiconductor industry, the evolution of power semiconductor, analog semiconductor and digital semiconductor technology has been around the development of low carbonization. For example, the evolution of digital chip process nodes all the way, the evolution of power semiconductor is mainly in the wafer part, constantly developing to smaller chip size and lower conduction impedance.

In the case Of silicon-based power semiconductors, high voltage Super Junction technology has basically reached its physical limit in terms of the Figure Of Merit coefficient (FOM value for short). In this case, packaging becomes the bottleneck that must be broken to continue to make better conduction impedance or energy efficiency.

One of Infineon's efforts to reduce carbon -- that is, to reduce energy consumption and improve efficiency -- is the JEDEC certified Top Cooling Package (TSC)." QDPAK and DDPAK top-cooled (TSC) packages for high-voltage mosFeTs, he said, adding that in addition to silicon-based power devices, the current hot silicon carbide (SiC), gallium nitride (GaN) and other third-generation semiconductors are also relying on newer packaging technology to bring chip performance to the extreme.

Advantages Of The Top Cooling Package

The top cooling (TSC) package is the predecessor of the QDPAK and DDPAK, which is actually the familiar DPAK (TO252) package. QDPAK is roughly equivalent to four DPAks side by side, while DDPAK is two DPAks side by side (Double DPAK).

The main advantages of this type of packaging are as follows:

1. To meet higher power requirements: optimize the use of circuit board space, Kelvin source pole connection, reduce the source pole parasitic inductance;

2. Increase the power density: the top heat dissipation can achieve the highest utilization of the circuit board;The optimized structure has low resistance and ultra-low parasitic inductance to achieve higher efficiency

3. Weight reduction: Integrated optimization of heat dissipation and heating helps to create a smaller case, thus reducing material use and weight

Application of The Top Cooling Package

However, as data centers, 4G and 5G wireless communication acer stations and other devices require higher and higher power density and smaller device sizes, they begin to require the use of less or no independent heat sink in circuit board design for power applications, and at the same time, more heat evenly distributed outside the entire device.

1. 5G Base Stations

In 5G or communications thermal management, base stations are currently designed to be fan-less, similar to the environment of mobile phone chargers. But base stations generally rely on closed metal shell heat dissipation, without the top with bare copper packaging, power devices can not effectively and evenly transfer heat to the shell.

2. Data Center

The second major scenario is the data center thermal solution, where, as the recent ChatGPT explosion shows, the endless human demand for data is growing at an almost exponential rate, placing greater demands on the efficiency of power conversion and the number of devices that can be installed in the same room size.

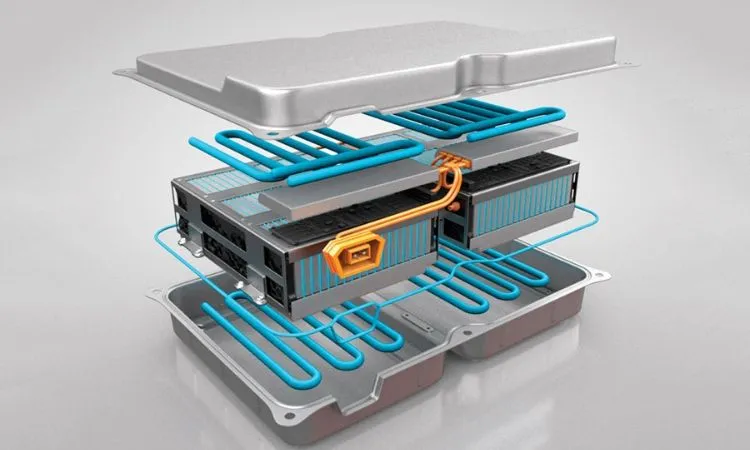

3. New Energy Vehicles

Another application scenario is new energy vehicles thermal solution. At present, in order to meet the design requirements of electric vehicles, the industry is constantly increasing the energy efficiency of power semiconductor, but also committed to reducing the PCB area occupied by it. At this time, the requirements for power density are also very high. Top cooling could help engineers design new energy vehicles with more space for the battery-powered part.

For IGBT heat sink, there are generally forced convection heat sinks. Of course, when the heat density is high, the bottom plate of the heat sink will adopt the way of buried heat pipes. Similarly, when the power density is greater than 1000W, the solution of liquid cooled plate is generally adopted to solve the problem of heat dissipation. Many IGBT chip factories will tell customers at least 2 more heat sink solution companies or solutions, so that customers can avoid the reason of only one supplier.