The design of liquid cooling plates, commonly used in various industries, plays a crucial role in ensuring efficient heat dissipation. However, it’s essential to consider the potential risks of liquid leakage during the design process to maintain the system’s performance and reliability.

Understanding the Design of Liquid Cooling Plates

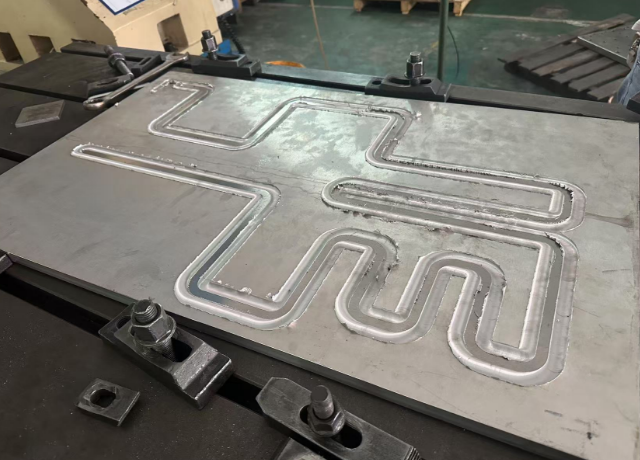

Typically, liquid cooling plates are made using an aluminum substrate with embedded copper tubes. The process starts by milling grooves into the aluminum using CNC technology. Next, the copper tubes, pre-bent into the desired shape, are pressed onto the aluminum using a punching machine. The gaps between the tubes and the aluminum are then filled with epoxy resin to reduce thermal resistance. This combination takes advantage of aluminum’s lightweight properties and copper’s high thermal conductivity.

Alternatively, engineers may opt for Friction Stir Welding (FSW) or Vacuum Brazing for joining materials. After assembly, two inlets and outlets are installed, allowing liquid refrigerants—usually water or a water-alcohol mix—to circulate, helping to dissipate heat. Water’s high thermal conductivity and specific heat capacity make it an ideal cooling agent. However, during cold environments, the risk of freezing arises, which is why mixing alcohol with water can prevent freezing and ensure continued heat dissipation.

Why Liquid Leakage is a Concern

Liquid leakage in the cooling plate is a significant issue. Engineers must carefully design the system to minimize the risk of leaks, as these can lead to:

- Reduced cooling efficiency, hindering heat dissipation.

- Damage to system components, affecting the reliability and lifespan of the equipment.

- Corrosion of electronic components and circuits, increasing the likelihood of system failure or even fire.

Common Causes of Liquid Leakage

- Material Stress and Surface Tension During the welding process, stress can build up in the materials, leading to minor cracks or deformations. These imperfections create small holes that allow the coolant to seep through.

- Installation and Process Deficiencies If the installation is not precise or welding and sealing processes are flawed, the risk of leaks increases. Issues like poor sealing or the aging of silicone rings can compromise the system, especially if the flatness of the aluminum plate is not properly maintained.

- Environmental Factors Temperature fluctuations, especially in high-pressure environments, can affect the integrity of the seals. Sealing failures may not be detectable during initial tests but can become apparent in real-world conditions. The design must account for thermal and cold shocks in the usage environment.

- Wettability Issues Coolants can have varying effects on the material surface. If the surface of the cooling plate is too rough or has microscopic defects, the coolant may penetrate more easily, increasing the likelihood of leakage.

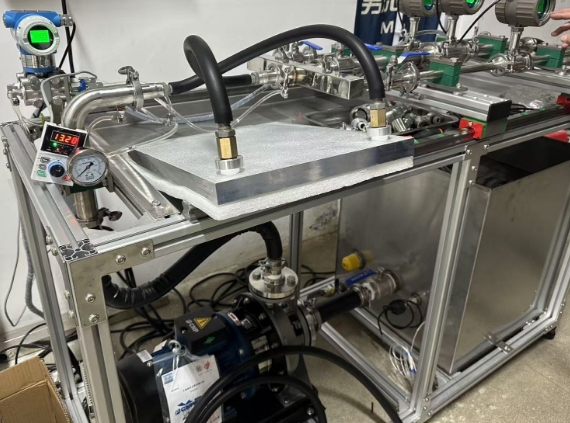

Testing for Potential Leakage Risks

To mitigate leakage risks, comprehensive testing is essential. We use various instruments to assess cooling plate integrity. These include differential pressure and holding pressure testing equipment. A holding pressure test typically lasts from 30 minutes to 2 hours. We simulate real-world conditions by adjusting the water temperature to mimic usage.

By considering these factors during the design phase, engineers can reduce the risk of leakage. This ensures better efficiency, longevity, and reliability of the liquid cooling plate.