Have you ever had to make the daunting decision between cost and quality when it comes to thermal management solutions? Is it always the case that quality comes with a hefty price tag, especially when talking about liquid cold plates? And does a smaller price tag necessarily mean lower quality?

When choosing liquid cold plates, an essential component for thermal management in many industries, it's crucial to strike a balance. While quality often comes at a higher price, understanding the intricacies of what you're paying for can lead to finding cost-effective solutions that do not compromise on performance.

If these questions have crossed your mind, then you are in the right place. Let's dive into the depths of cost vs. quality regarding liquid cold plates.

Does High Cost Always Equate to High Quality?

In many markets, there is a general assumption that higher cost is synonymous with higher quality. But is this principle always valid, especially when applied to liquid cold plates?

The reality is more nuanced. Cost and quality do exhibit correlation in the domain of liquid cold plates, but understanding why is crucial. Higher costs might be reflective of superior materials, innovative manufacturing processes, or advanced design – all contributing to enhanced performance and increased lifespan, thereby denoting higher quality.

Are Lower-Cost Liquid Cold Plates Always Inferior?

Given the argument that higher cost often aligns with higher quality, does that inherently mean cheaper liquid cold plates are of lower quality? Not necessarily.

While it is true that some low-cost liquid cold plates might save on manufacturing costs or use inferior materials, potentially compromising performance or lifespan, many cost-effective options in the market still deliver commendable performance. The key here is to understand what matters most for your specific application, and ensure those aren't compromised.

Evaluating the Quality of Liquid Cold Plates

To evaluate quality, you have to look beyond price tags. The evaluation process should encompass design, materials, manufacturing process, and of course, performance.

Consider the thermal conductivity of the materials used, the design's efficacy in facilitating heat transfer, and the manufacturing process's reliability. Performance tests can provide tangible data on the cooling efficiency, capacity, and durability of liquid cold plates.

The Balance Between Cost and Quality

Achieving a balance between cost and quality calls for a thorough understanding of your specific needs. Ask yourself – what are the cooling requirements of my application? How essential is the longevity of the cold plate? What is my budget allowance?

Identifying your requirements will help you find liquid cold plates that meet your needs without overshooting your budget. Often, a mid-range product might strike the perfect balance, offering quality performance without being overly expensive.

The Role of the Supplier in the Cost-Quality Equation

The supplier's role is critical when balancing cost and quality. Established suppliers often follow stringent quality control processes, ensuring that you receive a high-quality product regardless of the price point.

Suppliers like Kenfatech offer a range of liquid cold plates, catering to varied budgets. They provide options from cost-effective to high-end, ensuring choices for different budget brackets. Additionally, they also offer technical support, guiding customers in making informed decisions.

Long-Term Cost Considerations

When discussing cost and quality, it's essential to consider the long-term implications. For instance, investing in a higher-priced, high-quality liquid cold plate can lead to lower maintenance costs, reduced energy consumption, and increased longevity. These factors can offset the initial investment over time, making the high-quality option more cost-effective in the long run.

On the contrary, a cheaper, lower-quality liquid cold plate might require frequent replacements or repairs, leading to higher costs over time and reducing overall system efficiency. Therefore, while the initial cost may seem lower, the long-term costs could potentially be much higher.

Considerations for Large Scale Applications

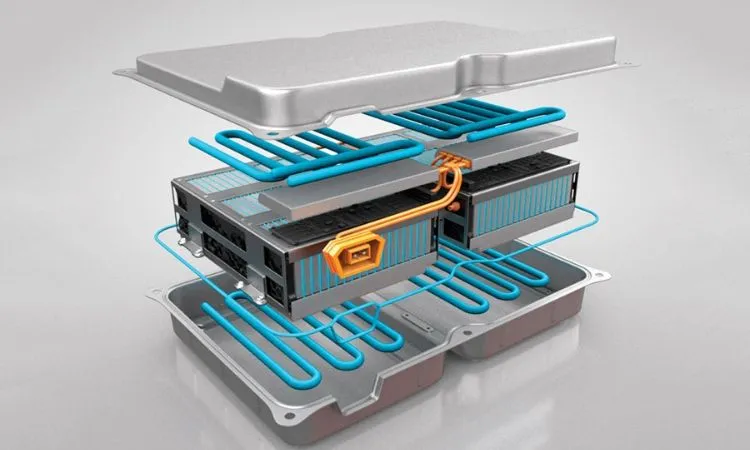

In large-scale applications such as data centers, electric vehicles, or industrial machinery, the cost-quality discussion becomes even more crucial. In these cases, any compromise on quality can lead to significant system inefficiencies, downtime, or damage, all of which can be far costlier than the initial saving from choosing a cheaper liquid cold plate.

A quality liquid cold plate ensures optimal system performance, reducing the risk of system failures and enhancing energy efficiency. These factors contribute to cost savings in the long run, proving that an investment in quality can indeed be a cost-effective decision.

Custom Liquid Cold Plates: Are they Worth it?

The discussion on cost and quality often leads us to custom liquid cold plates. These are specifically designed and manufactured to meet the unique requirements of your application. While they usually come with a higher price tag, custom liquid cold plates offer superior performance tailored to your needs.

Are they worth the cost? The answer lies in your specific application. If your cooling needs are unique or if standard liquid cold plates can't provide the efficiency you require, then the higher cost of custom liquid cold plates could be a worthy investment.

The Impact of Innovations and Technology Advancements

Innovation and technology advancements also play a significant role in the cost vs. quality discussion. New technologies can enhance the quality of liquid cold plates, offering better performance, increased durability, and improved energy efficiency. At the same time, advancements in manufacturing processes can reduce production costs, allowing for quality products at lower prices.

Staying updated with these advancements can help you make informed decisions, ensuring you get the best quality within your budget.

Conclusion

When it comes to liquid cold plates, the balance between cost and quality isn't a zero-sum game. With a clear understanding of your requirements, a careful evaluation of products, and the right supplier, you can find cost-effective solutions that don't compromise on quality. Remember, while the initial cost is a crucial factor, long-term considerations such as energy efficiency, maintenance costs, and product lifespan are equally important. So, make your decision wisely, ensuring you get the best return on your investment.