Case Studies-Copper tube process liquid cold plate with 6 pass tunnels

We will use professional thermal analysis software to design the optimal scheme for customers, then confirm the feasibility of the theory with engineers, and then start to make samples for testing

Copper tube process liquid cold plate with 6 pass tunnels

Project Details

Customer:

Automatic control manufacturer

Application:

Automatic control industry

Technology:

Copper tube liquid cold plates

Thermal power type:

IGBT cooling

Location:

Company patented product

Intruduction

Electronic components in special environments need a heat dissipation solution with low thermal resistance. Usually, this kind of copper tube or stainless steel tube is used as the channel of liquid fluid. The way of cooperation makes the copper tube and the aluminum plate closely linked, and there is no thermal resistance medium and gap in the middle. The epoxy resin is cured at room temperature, or the epoxy resin is cured quickly by heating, and then CNC processed. This high-efficiency heat dissipation method Water cooling plates are often used for 5G and Inverter Drive

The Thermal Solution

Designed requirements

Based on our more than 10 years of production experience, many customers need some standard water-cooled plates, which can reduce the production time of products. Therefore, our engineers spent some time to sort out and study, and obtained the specifications of heating chip modules used by general customers, so as to design the corresponding water-cooled plates. Customers just need to follow their own needs, approximate power, Basically you can choose our standard products. Generally speaking, we can provide samples within a week. At the same time, if you need to process the mounting holes on it, we can also provide services

PRODUCT SPECIFICATIONS

Plates Details: Extruded Aluminum 6063-T5

Tube Material: Copper 1100 9.52mm

ODx1.24mm wall

Standard Finish: Chromate Coating

Epoxy :Aluminum Filled –High thermal

Conductivity

Measurement :

177.8*152*14mm

177.8*305*14mm

177.8*610*14mm (the X length can be 152-1000mm)

The liquid cold plate sizes

After the software is run, the air volume pressure is obtained, so as to determine a reference value for the fan resistance impedance in the later period

Also, after the software is run, the speed of the air volume is obtained, so as to determine a reference value for the later fan air volume

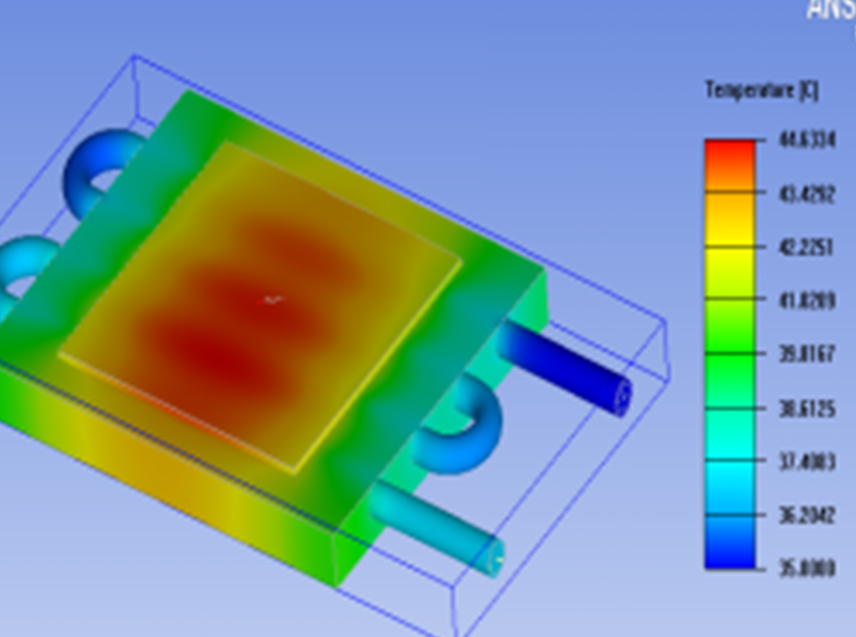

After calculation, the temperature distribution diagram of the heat source within the range of the set module is obtained, and then the engineer can optimize it.

Results

Thermal power @ 1000W

The ambient temperature is 35 °C

The flow of water 4LPM

Thermal resistance:(47.2-35)/1000=0.0122