Welcome to our blog post on cold forged heat sinks and their role in thermal management for automotive electronics. If you’re looking to customize your car radiator but need help determining which type is better for your car, you’ve come to the right place. In this post, we will explore how Cold Forged Radiator excel in thermal management for automotive electronics, providing you with the knowledge you need to make an informed decision. So let’s dive in!

What are Cold Forged Heat Sinks?

Cold forged heat sinks are an integral part of modern automotive electronics. They are used to dissipate the heat generated by the various electronic components in a car, ensuring optimal performance and reliability. But what exactly are Cold Forged Radiator?

Cold forging is a manufacturing process that involves shaping a metal while it is below its recrystallization temperature. This process produces heat sinks with high thermal conductivity, excellent structural stability, and better thermal dissipation capabilities than their counterparts.

The Advantages of Cold Forged Heat Sinks

Enhanced Thermal Conductivity

One of the critical advantages of cold forged heat sinks is their enhanced thermal conductivity. The unique manufacturing process ensures the heat sinks have high thermal conductivity, allowing for efficient heat transfer from the electronic components to the surrounding environment. This helps keep the temperature of automotive electronics at optimal levels, preventing overheating and subsequent damage.

Lightweight and Compact Design

Another significant advantage of Cold Forged Heat sink is their lightweight and compact design. These heat sinks are made from lightweight materials such as aluminum or copper, reducing the overall weight of the automotive electronics system. Additionally, the compact design allows easy integration into the limited space available in modern vehicles without compromising performance.

High Structural Stability

Cold forged heat sinks possess high structural stability thanks to the cold forging manufacturing process. This ensures that the heat sinks can withstand harsh operating conditions, vibrations, and shocks, commonly encountered in automotive environments. The stability of these heat sinks ensures the long-term reliability and durability of the thermal management system in automotive electronics.

Cost-Effective Solution

Cold forging offers a cost-effective solution compared to other heat sink manufacturing processes. The cold forging process allows for mass production of heat sinks with consistent quality, reducing manufacturing costs. Additionally, the lightweight nature of cold forged heat sinks leads to lower transportation costs and easier installation, further contributing to their cost efficiency.

Applications of Cold Forged Heat Sinks

Cold forged heat sinks find widespread applications in various automotive electronic systems. Some of the critical areas where these heat sinks excel in thermal management include:

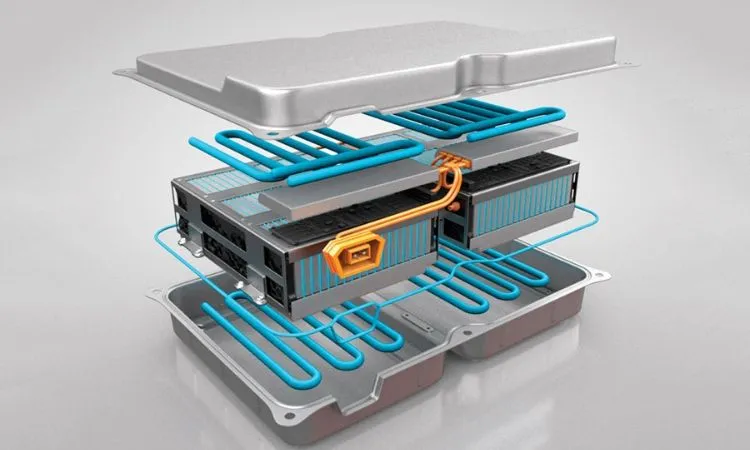

Electric Vehicle Battery Management

As the popularity of electric vehicles (EVs) continues to rise, effective battery management becomes crucial. Cold Forged Radiator play a vital role in cooling the battery systems of EVs, ensuring efficient and safe operation. Cold Forged Radiator prevent overheating and prolong the battery life by dissipating heat generated during the charging and discharging. Cold forged heat sinks prevent overheating and help extend the battery life.

Power Electronics

Power electronics, such as inverters, converters, and motor drives, are essential for modern vehicles. These components generate significant heat during operation, requiring adequate thermal management. Cold forged heat sinks provide an excellent solution for heat dissipation in power electronics, preventing performance degradation and extending the lifespan of these critical components.

LED Lighting Systems

Light-emitting diode (LED) lighting systems have become increasingly popular in automotive applications due to their energy efficiency and longevity. However, LEDs also generate heat, which needs to be effectively managed to ensure optimal performance. Cold Forged Radiator offer efficient thermal management solutions for LED lighting systems, improving their reliability and longevity.

Infotainment Systems

Infotainment systems in vehicles incorporate various electronic components, including processors, graphics cards, and amplifiers, which produce heat during operation. Failure to dissipate this heat properly can result in performance degradation and reduced lifespan of these systems. Cold Forged Radiator efficiently manage the heat generated by infotainment systems, avoiding these issues and ensuring uninterrupted performance.

How to Choose the Right Cold Forged Heat Sink for Your Car

Now that we have explored the advantages and applications of cold forged heat sinks in thermal management for automotive electronics, you might be wondering how to choose the right one for your car. Here are a few factors to consider:

- Heat Dissipation Requirements: Assess the heat dissipation requirements of your car’s electronic components and choose a cold forged heat sink that can efficiently handle the heat load.

- Size and Space Constraints: Consider the available space in your vehicle and choose a compact heat sink that can fit within the designated area without compromising other components.

- Material Selection: Evaluate the thermal conductivity, weight, and cost implications of different materials, such as aluminum or copper, to select the most suitable option.

- Manufacturing Quality: Ensure that the cold forged heat sinks you choose are manufactured with high-quality standards to guarantee their effectiveness and longevity.

- Consultation: If you need clarification on which cold forged heat sink is best for your car model, consider consulting with an automotive electronics expert who can provide valuable insights and recommendations.

Conclusion

In conclusion, Cold Forged Radiator excel in thermal management for automotive electronics. Their enhanced thermal conductivity, lightweight design, high structural stability, and cost-effectiveness make them ideal for dissipating heat in various automotive applications. Whether you’re looking to improve the performance of an electric vehicle, power electronics, LED lighting systems, or infotainment systems in your car, Cold Forged Radiator offer an efficient and reliable solution. Considering the heat dissipation requirements, size constraints, material selection, and consulting with experts if needed, you can choose the proper cold forged heat sink for your car and ensure optimal thermal management for your automotive electronics system.

Now that you have a deeper understanding of how cold forged heat sinks excel in thermal management for automotive electronics, you can confidently make decisions to customize your car radiator and improve its performance. Stay tuned for more informative content on automotive technology and customization!