104W natural convection heat sink design solution, using cold forging process design

We will use professional thermal analysis software to design the optimal scheme for customers, then confirm the feasibility of the theory with engineers, and then start to make samples for testing

Project Details

Customer:

LED manufacturer

Application:

LED lighting industry

Technology:

Cold forging process

Thermal power type:

LED cooling

Location:

Italy

Intruduction

The customer provides a general size, but it needs to be round. Besides, the fin sheet of the radiator needs to be round in shape, which should be due to natural convection. The circular radiation efficiency is the highest. Our engineers did CFD analysis based on this model and finally optimized a natural convection scheme

The Thermal Solution

Designed requirements

Power1 :8*8W+40w=104W;

Aluminum Material

Cold forging process

No fan and Normal convection

Environment 40℃

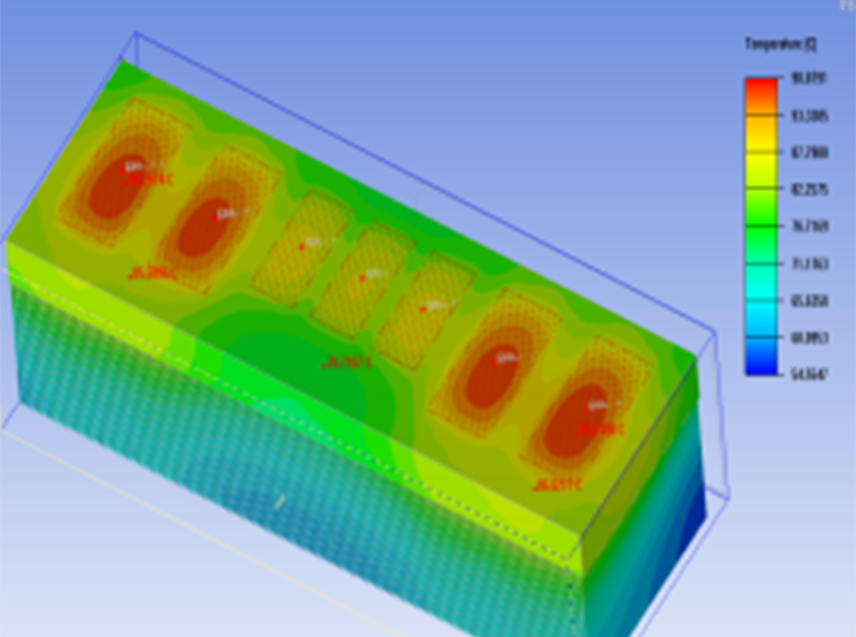

Simplified model and heat source in the Ansys software

Parameter setting and meshing are in the software

To solve the function calculation equation, make each curve function equation convergent based on the set parameters

After calculation, the temperature distribution diagram of the heat source within the range of the set module is obtained, and then the engineer can optimize it.

Results

Our engineers use detailed data and accurate meshing CFD software for calculation. By constantly adjusting the data module, heat pipe position, and thickness and spacing of heat sinks fins, we finally designed a heat sink scheme meeting the requirements for the customer. Meanwhile, we have made sample testing and mass production. However, the heat pipe heat sink should be noted that in extreme environment, the liquid inside the heat pipe is easy to freeze and then expand. Used the simple model method, the result will be different from the actual module. The heat sink surface Max temperature is 94.17℃