AL Vapor Chambers

generally called flat heat pipe, uniform temperature plate and soaking plate. With the continuous improvement of chip power density, VC has been widely used in the heat dissipation of CPU, NP, ASIC, mobile phone, computer, base station, electronic components and other large power devices.

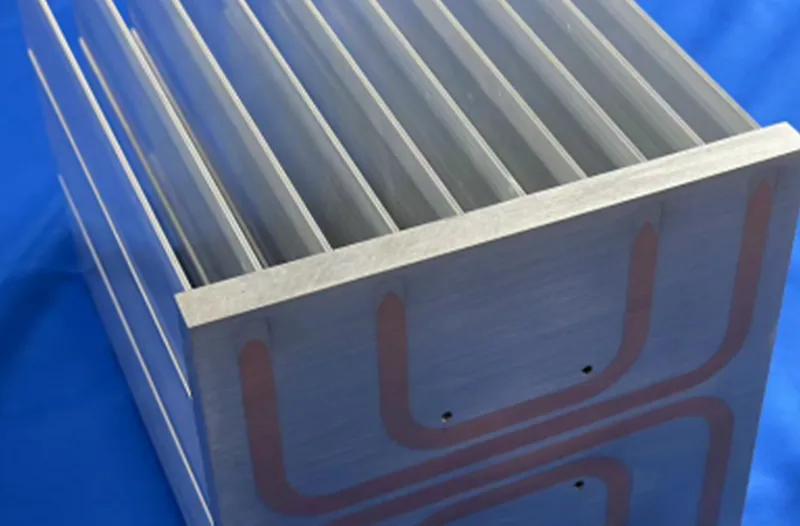

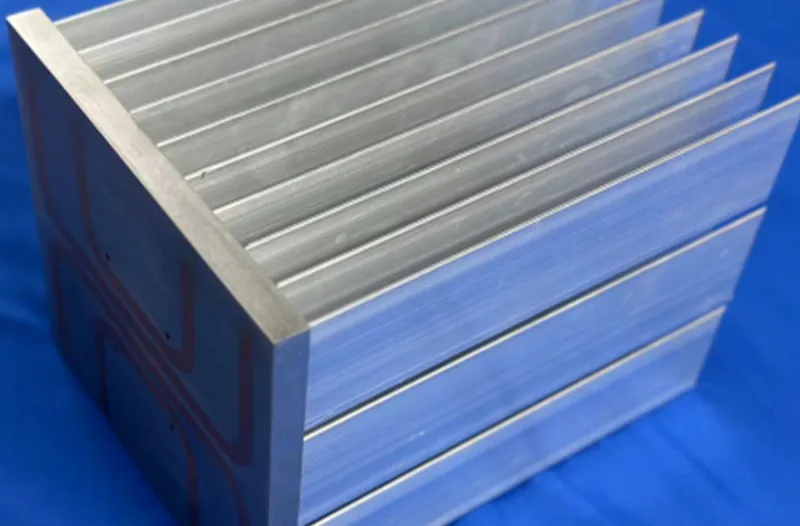

Aluminum VC heat sink, bonded with epoxying is used for cooling of 600W high power LED chips .Natural convection is adopted, and the direction of gravity is horizontal.The product size is 250x250x300mm

At present, the high power LED heat sink is generally produced by cold forging or die casting process.But these are very low power scheme design, if encounter high power LED heat dissipation, especially with the size requirements of the heat dissipation scheme, these traditional schemes are basically unable to meet,This is mainly because naturally dissipated radiators need surface area and convection space, so we designed a heat sink made of aluminum VC fins.

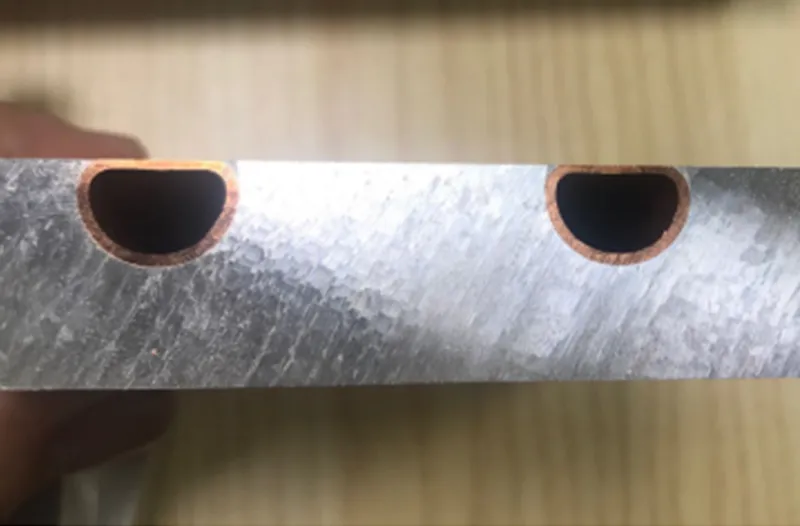

As the LED light source is the COB integrated light source, we need to use high-power heat pipe at the bottom of the heat sink to evenly distribute the heat to the entire bottom plate, and then transfer it to the aluminum VC by way of conduction.We pay great attention to the contact mode between heat pipes and aluminum bottom plate to minimize the thermal resistance between them, so we use soldering paste welding, heat pipes and bottom plate with our special slot, the connection is very close.

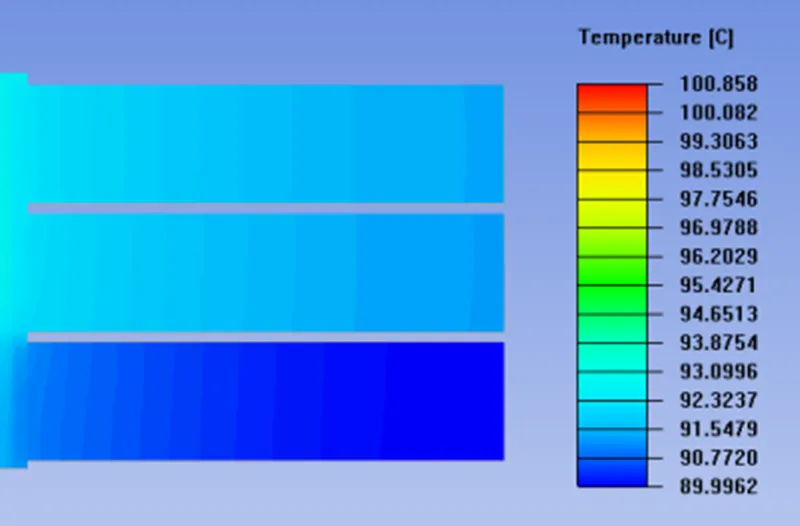

Before making the sample, we also did thermal analysis test with the customer.

And the result showed that under the condition of ambient temperature of 40 degrees, the maximum temperature of the bottom plate was displayed at about 100 degrees, which met the customer’s demand below 105 degrees.LED power is 600W, heating size is 45x55mm area.

When the heat sink was finished, we tested it with a high-power LED chip according to the customer’s requirements. The voltage was 37V, the current was about 16A, and the power of the whole product was 600W. In the actual test, the temperature of the bottom plate of the product was about 85 degrees and the ambient temperature was 30 degrees. (This is consistent with the thermal analysis we did before when the ambient temperature is 10 degrees and the highest temperature is 100 degrees)

The characteristics of our company's aluminum VC

1. Mature design. Our structure design has been tested by GJB-150, the structure is mature and reliable;

2. Light weight and good heat conduction. Hollow aluminum alloy structure, the weight is only the same volume of solid aluminum 50 ~ 90%, and the heat conduction capacity is more than 100 times of aluminum;

3. Easy to process. Aluminum alloy material has good thermal conductivity, excellent processing performance, convenient processing into various shapes, but also convenient integration with structural parts, so that the equipment or instruments can have the lightest weight and the best heat dissipation.

4. Low temperature resistance. Aluminum homogeneous plate commonly used acetone as the working medium, the freezing point is lower than -90℃, there will not be the problem of water icing expansion damage to the internal structure;

5. Cost-effective. Aluminum VC plate conducts heat well, and the volume cost is only 1/10 of copper, the same size under the highest cost-effective;