AL Vapor Chambers

generally called flat heat pipe, uniform temperature plate and soaking plate. With the continuous improvement of chip power density, VC has been widely used in the heat dissipation of CPU, NP, ASIC, mobile phone, computer, base station, electronic components and other large power devices.

A kind of high efficiency heat conduction material, AL Vapor Chambers.This product is usually used in the environment with small space and high heat density. When the area is large enough, it can be used for natural heat dissipation of high-power LED.

The VC plate is mainly composed of bottom plate (evaporating zone), upper cover (condensing zone), capillary structure inside bottom plate and upper cover (providing liquid reflux capillary), aluminum column aluminum ring between bottom plate and upper cover (providing liquid reflux from condensing zone to evaporating zone) and a small amount of working liquid. The low vacuum in the container makes the working medium very easy to boil. Its working principle is that the working liquid in the closed container quickly turns into steam after absorbing heat, and the steam is driven by the steam pressure to the condensing area. The latent heat of the working medium is used for heat transfer. Thus the cycle of the whole heat transfer process starts again. The container material of Kenfa Tech electronic material superconducting hot soaking plate is mainly aluminum alloy 6063 or 6101, and the working medium can be pure water, methanol and acetone. The shape of superconducting soaking plate can be planar or three-dimensional.

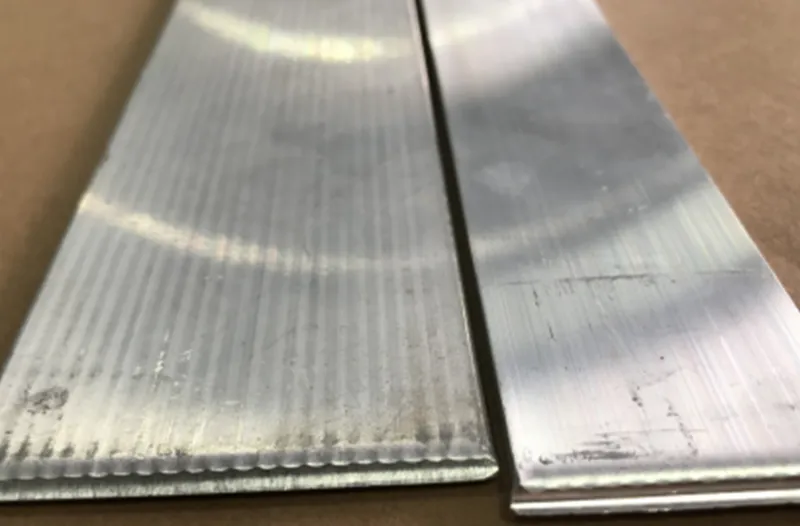

A preparation method of aluminum VC soaking plate capillary core. The simulation confirms that the porosity of the soaking plate capillary core is 40%-70%, and the processing index is 50-100um in diameter. According to different porosity, aluminum is mixed in different proportions Aluminum powder and aluminum silicon powder, and whether to add pore-forming agent, aluminum silicon powder fills the gap between aluminum powder particles to form a connection, as sintering powder, spread it on the tooling to be sintered, and process it to imitate the shape and thickness of the sintered core to ensure the thickness of the powder coating The consistency of the core to be sintered and the tool to be sintered are placed in a vacuum furnace, pressurized at 0.15‑0.2MPa, vacuum at 1.5×10‑3Pa, heated for 40min to 400°C for 60min, then heated for 40min to 500°C for 60min , reheat for 20min to 580°C, last for 20min, cool down with the furnace, high strength, high reliability, boil the workpiece in hot water for 1 hour, remove the pore-forming agent, and then dry, low requirements for equipment and tooling, low cost , Easy to form.

By simulation calculation, it is confirmed that the porosity of the capillary core of the soaking plate is 40%-70% and the pore size is 50-100μm. According to different porosity, aluminum powder and aluminum silicon powder should be mixed in different proportions: if the porosity index is 40%-50%, aluminum powder and aluminum silicon powder should be mixed in a ratio of 3:1; If the porosity index is 50%-60%, aluminum powder and aluminum silicon powder shall be mixed in a ratio of 4:1; If the porosity index is 60%-70%, NaCl powder with particle size of 50μm-100μm is added, and the mixture is evenly mixed by mechanical method. Aluminum powder, aluminum silicon powder and pore-making agent are mixed in a ratio of 8:2:1. Lay on the tooling to be sintered, and process the shape and thickness of the sintered core. The core to be sintered and the tooling to be sintered were placed in a vacuum furnace, pressurized 0.15-0.2MPa, vacuum degree 1.5×10-3Pa, heated 40min to 400℃ for 60min, reheated 40min to 500℃ for 60min, reheated 20min to 580℃ for 20min, then cooled down with the furnace; The workpiece is boiled in hot water for 1 hour, the pore-making agent is removed, and then dried.

The characteristics of our company's aluminum VC

1. Mature design. Our structure design has been tested by GJB-150, the structure is mature and reliable;

2. Light weight and good heat conduction. Hollow aluminum alloy structure, the weight is only the same volume of solid aluminum 50 ~ 90%, and the heat conduction capacity is more than 100 times of aluminum;

3. Easy to process. Aluminum alloy material has good thermal conductivity, excellent processing performance, convenient processing into various shapes, but also convenient integration with structural parts, so that the equipment or instruments can have the lightest weight and the best heat dissipation.

4. Low temperature resistance. Aluminum homogeneous plate commonly used acetone as the working medium, the freezing point is lower than -90℃, there will not be the problem of water icing expansion damage to the internal structure;

5. Cost-effective. Aluminum VC plate conducts heat well, and the volume cost is only 1/10 of copper, the same size under the highest cost-effective;

Our company's customized conditions for aluminum VC:

1,Material: The most commonly used 6063 aluminum alloy, can also use 6061 aluminum alloy, or 1 series aluminum alloy, 3 series aluminum alloy;

2. Size: Maximum size 400mm*400mm;

3. Working temperature range: -60 ~ 140℃. Special working medium can have higher or lower operating temperature;

4. Surface treatment: conductive oxidation, anodic oxidation, hard anode, spray paint, etc.

5. Other requirements, such as acceleration, vibration, impact, high and low temperature, etc. shall be negotiated by both parties according to customer requirements;

6. Processing cycle: 21 days for making sample.