LEDs generate a significant amount of heat during operation, and if not properly cooled, it can result in increased LED temperatures, affecting their performance and lifespan. Here are some suggestions on how to use a high-power heat pipe heat sink for LED cooling:

- Select an appropriate heat pipe heat sink: Choose a suitable high-power heat pipe heat sink based on the LED power and cooling requirements. Heat pipe heat sinks come in various specifications and sizes, and you can select the most suitable one based on the heat generated by the LED and the physical space available.

- Install the heat sink properly: Install the heat pipe heat sink correctly onto the LED component. Ensure proper contact between the heat sink and the LED component’s surface, and use appropriate thermal interface materials (such as thermal paste) to fill any gaps, maximizing heat transfer efficiency.

- Ensure good ventilation: To allow the heat pipe heat sink to dissipate heat effectively, ensure that the environment where the LED is located has good ventilation. Ensure proper airflow by promoting air circulation, such as using fans or air ducts, to help the heat sink expel heat quickly.

- Consider the overall cooling system: In addition to the heat pipe heat sink, you can consider other cooling measures to enhance overall cooling efficiency. For example, combining heat sinks, cooling fans, and airflow channels to form a complete cooling system can further improve LED heat dissipation.

- Regular cleaning and maintenance: LED heat sinks and their surrounding environment can accumulate dust and dirt, which can impact cooling performance. Therefore, regular cleaning and maintenance of the heat pipe heat sink are essential to ensure its proper functioning and efficient heat dissipation.

In conclusion, a high-power heat pipe heat sink is a reliable cooling solution for LED heat dissipation. By selecting the appropriate heat sink, installing and maintaining it correctly, and incorporating other cooling measures, it is possible to effectively reduce LED temperatures, improving their performance and lifespan.

The heat pipe is directly in contact with the heat source, which can greatly improve the performance of the heat sink by using the efficient heat transfer effect.

Directly contacting the heat source with a heat pipe can greatly enhance the performance of a heat sink by utilizing its efficient heat transfer capability.

Heat pipes are indeed used to enhance the performance of heat sinks due to their high-efficiency heat conduction properties. A heat pipe is a heat transfer device typically consisting of a sealed pipe filled with a working fluid (a special type of liquid or gas). Its operation is based on the process of evaporation and condensation of the fluid or gas within the heat pipe, driven by a temperature gradient.

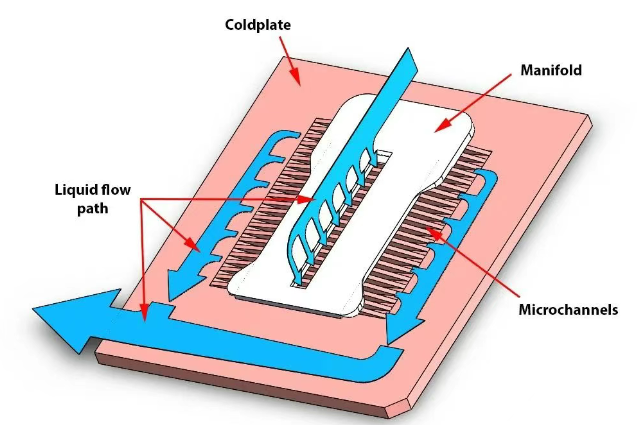

A heat pipe typically consists of an evaporator section on the side facing the heat source, a heat transfer pipe, and a condenser section on the other side facing the heat sink. When the evaporator section on the heat source side is heated, the working fluid evaporates into a gas, absorbing a large amount of heat. This heat is then transferred through the heat transfer pipe to the condenser section on the heat sink side. In the condenser section, the working fluid cools down and condenses back into a liquid, releasing the absorbed heat. The liquid returns to the evaporator section through capillary action or gravity, and the cycle starts again.

The heat transfer mechanism of a heat pipe is highly efficient because the evaporation and condensation processes of the working fluid enable rapid heat transfer between the heat source and the heat sink. By directly contacting the heat pipe with the heat source, the heat generated by the source can be effectively transferred to the heat sink, thereby improving the heat dissipation performance of the heat sink.

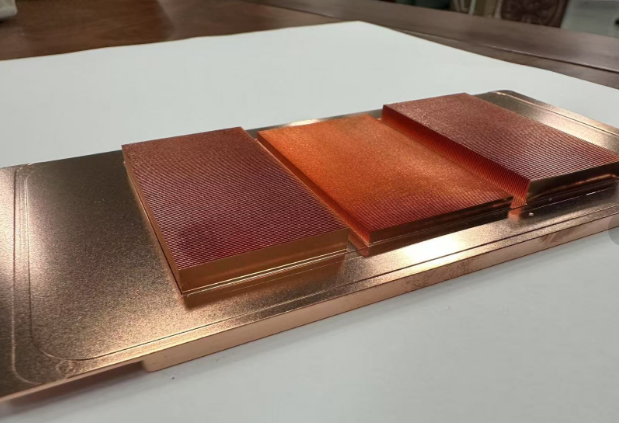

The heat pipe is directly in contact with the heat source, which reduces the heat transfer resistance between the heat sink bottom plate and the heat source. We have done a lot of tests and products, and come to the conclusion that this design method of direct contact with the heat source can reduce the chip temperature by about 5-8 degrees under the same conditions.