Innovative Skived Fin Heat Sinks Manufacturer

Advanced technologies for precise temperature control and improved energy efficiency. Kenfatech is your trusted partner for high-performing skived fin heat sinks

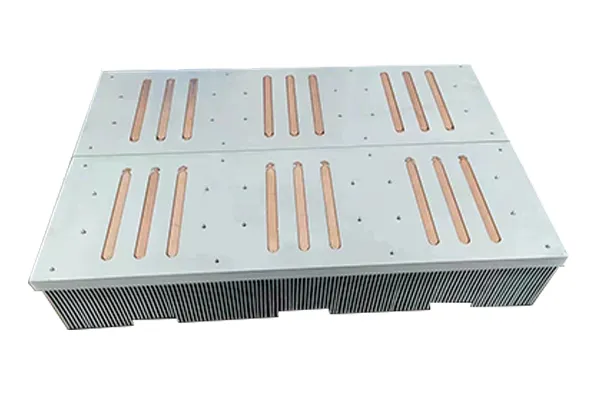

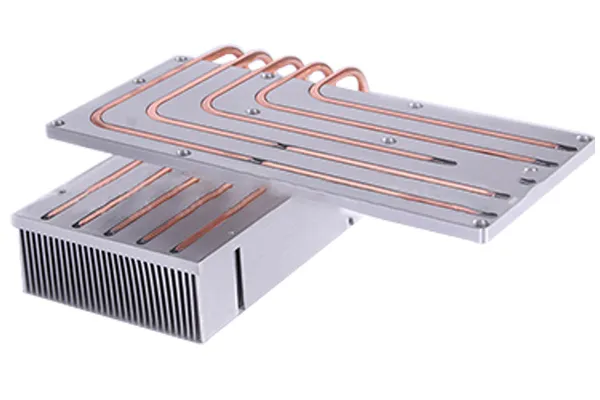

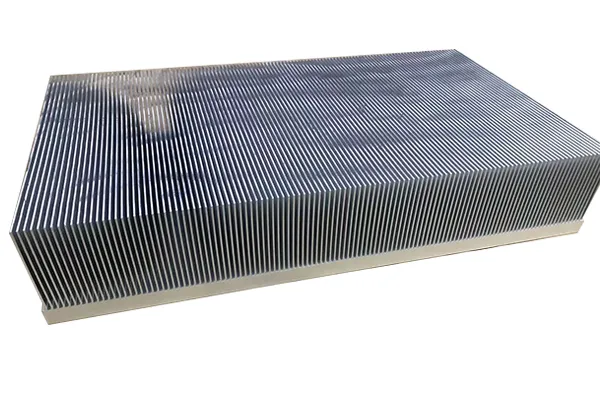

Skived Fin Heat Sink

Kenfatech is a company with 10 years of experience in heat sink fabrication. We are equipped with expert engineers that assist in customizing your ideal design of the skived fin heat sink.

Kenfatech skived fin heat sink is trusted by the worldwide leading brands over 1000 clients. We manufacture different types of the heat sink with the following techniques: die casting, machining, extrusion, forging, skiving fins, etc.

Send us your skived fin heatsinks and let’s discuss, Kenfatech guarantees to supply cost-effective with premier quality.

Explore Our Skived Fin Heat Sinks Gallery

How Kenfatech Works

Get the customer's needs

We usually get some heat sinks or cooling system design requirements from our customers

Design or DFM

After receiving the drawings of existing designs, our engineers will conduct a DFM evaluation. In addition, for some customer-oriented conceptual designs, our engineers are required to perform structural design and thermal protection analysis.

Making Samples

After getting the customer's confirmation of the drawing, we will arrange the production of the sample, which usually takes 3-4 weeks to complete according to the customer's payment date

Customer Confirmation

After the customer's test, finally determine whether to meet the requirements

Quality Assurance for Skived Fin Heat Sinks:

Kenfatech prioritizes quality, employing strict controls to ensure product reliability. Each liquid cold plate is rigorously tested for thermal performance, integrity, and fluid-tightness. Our expert team oversees every production phase, ensuring excellence.

We’ve strategized production and supply chain management to address prevalent industry issues like quality concerns and delivery delays. We provide punctual deliveries without compromising quality by aligning our production schedules with client timelines. Choose Kenfatech for impeccable quality, timely deliveries, and seamless service.

Why Choose Kenfatech's Skived Fin Heat Sinks?

Design and Development Expertise

Our team's proficiency in creating tailored liquid cold plate solutions sets us apart. We harness our deep understanding of thermal dynamics to design products that meet your specific needs.

Quality Assurance

We implement stringent quality control measures, ensuring the reliability and durability of our products. Our skived fin heat sinks stand the test of time, providing a robust solution for your cooling needs.

Cost Efficiently

Relying on our one-stop design and manufacturing services, we can provide you with the most cost-effective solutions. Thousands of existing size save your cost efficiently

Timely Delivery

We understand the importance of time in business. Our efficient production management protocols ensure we deliver high-quality products right when you need them.

Customer Service

Our commitment extends beyond product delivery. We provide exceptional customer support, assisting you at every step of your journey with us. deliver high-quality products right when you need them.

Proven Track Record

Our track record of successful collaborations across various industries speaks volumes. Companies worldwide trust Kenfatech to provide them with top-notch thermal management solutions.

Custom Liquid Cold Plate with Easy

– OEM/ODM for customers.

– Lead time 3 to 4 weeks.

– ERP system control process.

– ISO9001:2015 Certified Factory

– IATF 16949:2016

– More than 10 years making heat sinks experience.

– Professional thermal analysis software (Icepak,Ansys,Qfin )

– Engineer 1 to 1 project management and technical support.

– Reliable after-sales service

Get A Free Quote

Contact us to get a free quote and more expertise about custom Liquid Cold Plate. Your project will meet a right solution with Kenfatech.