Laser-Thermal Solution Design

We will use professional thermal analysis software to design the optimal scheme for customers, then confirm the feasibility of the theory with engineers, and then start to make samples for testing

The 3600W liquid cooling plate is designed for laser pumping source heat dissipation

Project Details

Customer:

Laser semiconductor

Application:

Pumping source

Technology:

Liquid cold plate

Thermal power type:

600X6=3600W

Location:

China

Intruduction

We met a customer who needed a heat dissipation solution for their laser pumping source. Our engineers initially tried using air-cooled forced convection and a skived fin heat sink with heat pipe process, but found that the temperature was still too high to meet the customer's requirements. After utilizing the most reliable and efficient friction stir welding process, we were able to provide a solution that satisfied the customer's needs and passed all proofing tests.

Project challenge

The customer provides a high-power pump source of liquid cooling plate heat dissipation needs, power density is very large, and the product size is only 550x450x20mm, in such a small volume of liquid cooling plate, to solve the heat of 3600W, theoretically, each module needs to do the Micro flow channel, but after evaluating the processing cost found that the cost of CNC machining is very high. And the customer is also difficult to bear this cost, for the pump source temperature, but also must control the temperature difference within 10 degrees, so these conditions are very challenging

Solution

We used AL6063 material and annealed the aluminum plate for hardness treatment. If not treated, stress would be released during CNC machining, causing deformation of the product surface. Typically, we heat it in an oven at 350 degrees for eight hours and then slowly let the temperature drop over a four-hour period.The product size is 550x450x20mm;The flow channel is in series and has a cross-sectional area of 12X12mm.The whole flow path can be completed by friction stir welding process, and this processing method can control the cost.Therefore, the customer is also very happy to have such a cost-effective liquid cooling plate solution, which can be implemented into mass production.

Thermal Design

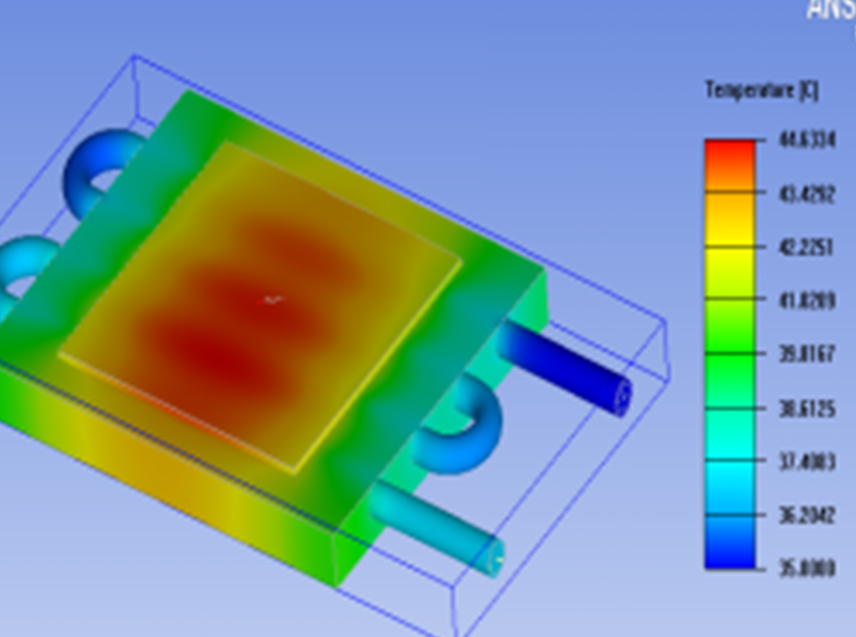

Engineers set the operating mode to turbulence, regardless of gravity and radiation. The final temperature is shown in the figure.The thermal power is 3600W and the water flow rate is 8 L/min.

Was the purpose of the design achieved?

We adopted the friction stir welding process and finally completed production of the sample. There were no issues with production or quality throughout the entire process, which proves that our design and process are feasible. The cooling plate underwent a leakage and pressure holding test, reaching a maximum pressure of 1.2Mpa without deformation or leakage; it also passed a 0.7Mpa pressure holding test for 20 minutes without any signs of leakage.