As data centers and AI facilities demand more computing power, they also generate more heat. Two-phase cooling has emerged as a game-changing technology in the thermal management industry. But what exactly is it? And why should you care? Let’s dive in!

| Cooling Method | Energy Efficiency | Heat Transfer Efficiency | Environmental Impact | Ideal Applications |

|---|---|---|---|---|

| Two-Phase Cooling | High | Enhanced by phase change | Variable (depends on coolant) | Data centers, AI, HPC |

| Single-Phase Cooling | Medium | Limited by heat capacity | Generally lower impact | General computing |

| Air Cooling | Low | Limited by air’s heat capacity | Low environmental impact | Basic computing needs |

What Is Two-Phase Cooling and Why It Matters

Two-phase cooling is an advanced thermal management technology that uses the phase change of a liquid coolant to vapor to efficiently remove heat from electronic components. Unlike traditional cooling methods, two-phase cooling takes advantage of the latent heat of vaporization – the energy absorbed when a liquid changes to a gas.

In today’s high-tech world, thermal management is becoming increasingly important. For instance, modern AI processors can generate heat equivalent to a small cooking stove! Therefore, finding efficient cooling solutions is not just nice to have – it’s essential for performance and longevity.

The Growing Need for Advanced Cooling

With the rise of cloud computing and artificial intelligence, the heat generated by processing units has skyrocketed. Traditional cooling methods simply can’t keep up, which is why innovations like two-phase cooling have become so important.

According to Dr. James Reynolds, thermal engineering expert at Stanford University, Two-phase cooling represents the most significant advancement in thermal management technology in the last decade. It’s a crucial development for sustaining the exponential growth we’re seeing in computing power.

The Business Impact

The financial implications of inefficient cooling are substantial. Overheating can lead to:

- Reduced component lifespan

- System throttling and performance drops

- Higher electricity bills

- Increased risk of system failures

Therefore, investing in advanced cooling technology like two-phase systems isn’t just a technical decision – it’s a smart business move that can lead to significant cost savings over time.

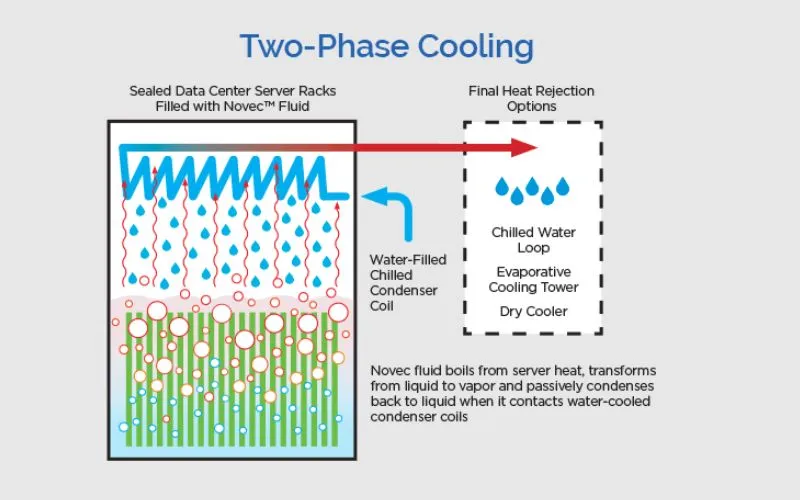

How Two-Phase Cooling Works: A Simple Explanation

Two-phase cooling might sound complex, but the basic principle is actually quite straightforward. Let’s break it down step by step:

The Cooling Cycle

- Heat Absorption: Electronic components are submerged in or come in contact with a special dielectric liquid coolant.

- Phase Change: As the components generate heat, the liquid absorbs this heat and begins to boil, changing from liquid to vapor.

- Heat Transport: The vapor, now carrying the heat energy, naturally rises away from the components.

- Condensation: The vapor reaches a cooler surface (usually a heat rejection unit or condenser) and changes back into liquid.

- Return: The cooled liquid returns to the components, and the cycle repeats.

The Science Behind It

What makes two-phase cooling so efficient is the physics of phase change. When a liquid changes to vapor, it absorbs a large amount of heat energy without a significant increase in temperature. This property, known as the latent heat of vaporization, allows two-phase systems to handle high heat loads more efficiently than single-phase cooling, which relies solely on a temperature difference to transfer heat.

To put this in perspective, water at its boiling point can absorb about 5-10 times more heat energy when changing to steam than it can through simple heating without phase change. This remarkable property is what gives two-phase cooling its edge.

Types of Two-Phase Cooling Systems

There are several implementations of two-phase cooling technology:

- Immersion Cooling: Components are fully submerged in the dielectric fluid.

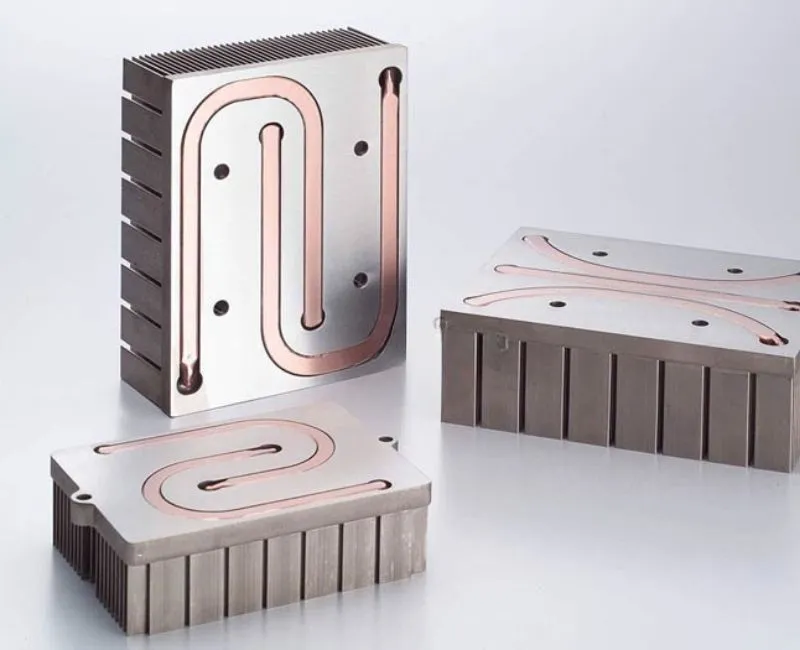

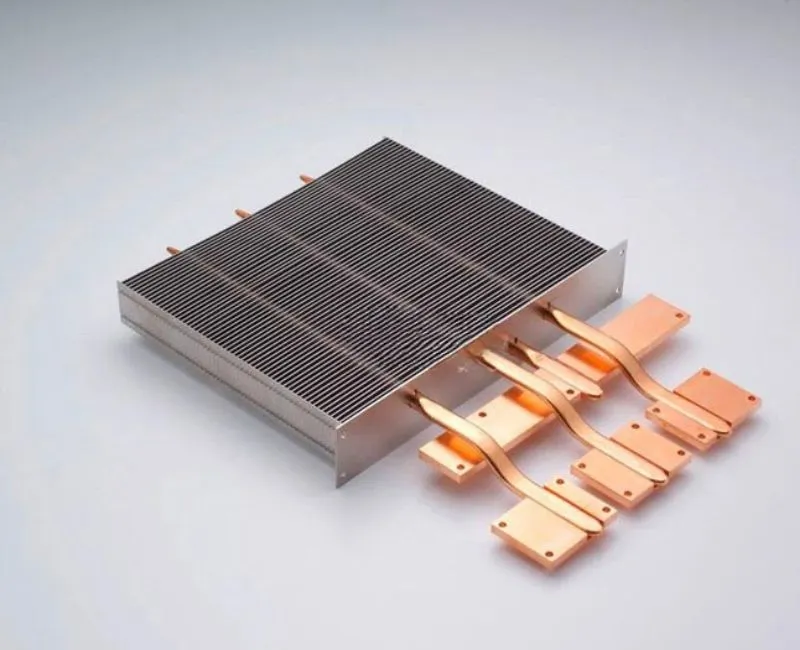

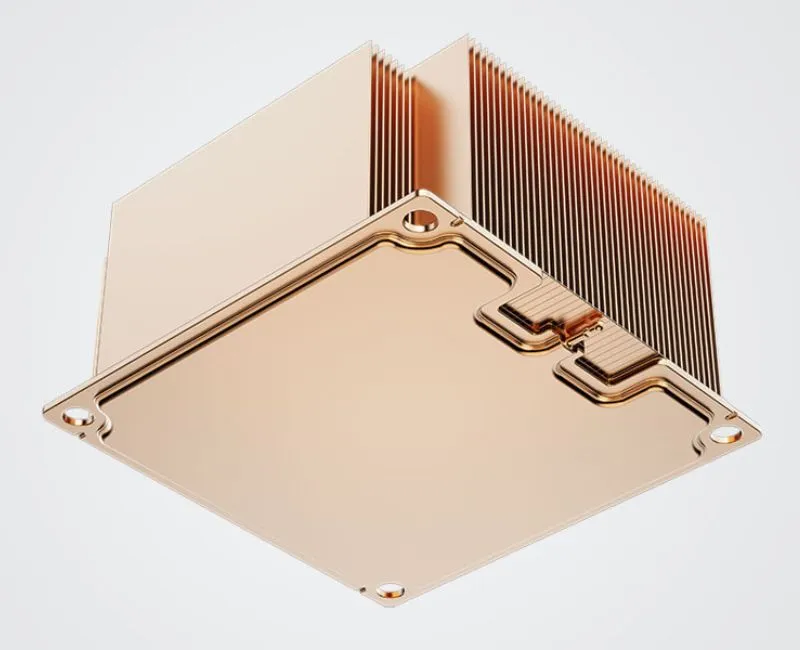

- Heat Pipes: Sealed copper tubes containing a small amount of fluid that undergoes phase change. Heat pipe assemblies are commonly used in various applications.

- Vapor Chambers: Flat, enclosed chambers that work on the same principle as heat pipes but spread heat in two dimensions.

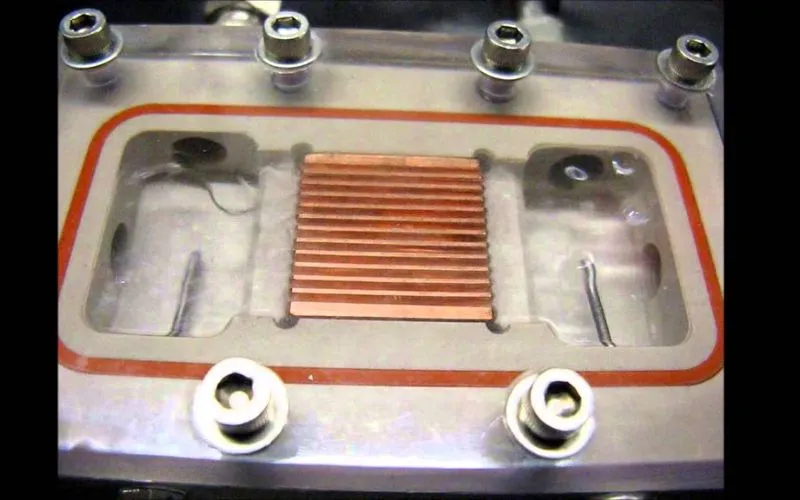

- Two-Phase Cold Plates: Similar to liquid cold plates but utilizing phase change for enhanced efficiency.

Each type has its own advantages and is suitable for different applications depending on space constraints, cooling requirements, and budget considerations.

Two-Phase vs. Single-Phase Cooling: Key Differences

To truly appreciate the advantages of two-phase cooling, it’s helpful to compare it directly with single-phase cooling systems, which are still the industry standard in many applications.

| Feature | Two-Phase Cooling | Single-Phase Cooling |

|---|---|---|

| Coolant Behavior | Changes from liquid to vapor | Remains in liquid state |

| Heat Transfer Mechanism | Latent heat (phase change) | Sensible heat (temperature change) |

| Cooling Efficiency | High (5-10x more efficient) | Moderate |

| Energy Consumption | Lower due to passive heat transfer | Higher due to pumps and fans |

| Temperature Uniformity | Excellent (isothermal operation) | Variable (temperature gradients) |

| System Complexity | Moderate to high | Low to moderate |

| Initial Cost | Higher | Lower |

| Maintenance Requirements | Generally lower | Regular maintenance needed |

Practical Implications of the Differences

The theoretical differences between these cooling methods translate into real-world impacts:

Temperature Stability

In a single-phase system, the coolant gets progressively warmer as it absorbs heat, creating temperature gradients. In contrast, two-phase cooling systems maintain more consistent temperatures across the cooled components because the phase change occurs at a constant temperature. This temperature stability is crucial for sensitive electronics that need to operate within specific temperature ranges.

Space Efficiency

Two-phase cooling systems can often be more compact while delivering the same cooling capacity. This space efficiency is particularly valuable in densely packed environments like data centers or inside slim devices like high-performance laptops.

Pumping Power

Single-phase systems typically require powerful pumps to move liquid coolant at high flow rates. Two-phase systems can often operate with reduced pumping power because the vapor movement happens naturally due to buoyancy, and the condensation cycle can be driven by gravity in many designs.

When to Choose Each Technology

Despite the advantages of two-phase cooling, single-phase cooling remains the better choice in some scenarios:

- Two-phase cooling excels in:

- High-density computing environments

- Applications with power densities above 500 W/cm²

- Situations where temperature uniformity is critical

- Systems where energy efficiency is paramount

- Single-phase cooling remains preferable for:

- Lower-power applications

- Budget-constrained projects

- Systems where simplicity is valued over maximum efficiency

- Applications with less extreme temperature requirements

According to thermal engineering specialist Dr. Elena Kovacs, The decision between single-phase and two-phase cooling should be driven by your specific heat load, space constraints, and budget. While two-phase cooling offers superior thermal performance, single-phase systems remain cost-effective for many mainstream applications.

Major Benefits of Two-Phase Cooling Technology

Two-phase cooling offers numerous advantages that make it increasingly popular for high-performance computing and other applications requiring efficient thermal management. Let’s explore these benefits in detail.

Superior Energy Efficiency

One of the most compelling benefits of two-phase cooling is its remarkable energy efficiency. Traditional cooling systems typically require significant energy for pumps and fans to move coolant or air. In contrast, two-phase cooling systems leverage the natural physics of phase change to transport heat with minimal external energy input.

In practical terms, data centers implementing two-phase cooling technologies have reported energy savings of 25-30% compared to conventional cooling approaches. This translates directly to lower operational costs and reduced carbon footprints.

Exceptional Cooling Capacity

Two-phase cooling systems excel at handling high heat loads that would overwhelm traditional cooling methods. This is particularly valuable for:

- High-performance computing clusters

- AI and machine learning hardware

- Power electronics in electric vehicles

- Telecommunications equipment

For perspective, while air cooling typically struggles beyond 150 W/cm², and single-phase liquid cooling reaches limits around 500 W/cm², two-phase systems can efficiently handle heat fluxes exceeding 1000 W/cm² in some configurations.

Enhanced Reliability and Longevity

The reliability advantages of two-phase cooling systems cannot be overstated:

Temperature Stability

By maintaining more consistent temperatures, two-phase cooling reduces thermal cycling – a major cause of component failure due to expansion and contraction. This temperature stability extends the lifespan of sensitive electronics significantly.

Reduced Mechanical Complexity

Many two-phase cooling implementations, such as heat pipes and vapor chambers, have no moving parts. This inherently increases reliability compared to systems dependent on fans and pumps that can fail.

Environmental Protection

In immersion cooling variants, components are protected from environmental contaminants like dust and humidity, eliminating common causes of electronic failure.

According to a survey by the Uptime Institute, cooling system failures account for approximately 15% of data center outages. Two-phase cooling technologies can significantly reduce this risk factor.

Cost Considerations Over Time

While two-phase cooling systems often require a higher initial investment, the total cost of ownership (TCO) analysis typically favors these advanced solutions:

Initial Costs

Two-phase cooling systems generally have higher upfront costs due to specialized components and coolants. However, these costs are continually decreasing as the technology becomes more mainstream.

Operational Savings

The significant energy efficiency advantages translate to lower electricity bills over the system’s lifespan. For large-scale operations like data centers, these savings can be substantial – often recouping the additional initial investment within 18-36 months.

Space Utilization

The superior cooling efficiency allows for higher density computing, making better use of valuable real estate. This space optimization represents another form of cost savings, especially in locations where square footage is expensive.

Maintenance Expenses

Many two-phase cooling solutions require less frequent maintenance, further reducing long-term operational costs. Passive two-phase systems like heat pipe assemblies are particularly advantageous in this regard.

Real-World Applications of Two-Phase Cooling

Two-phase cooling technology is revolutionizing thermal management across numerous industries. Here’s how different sectors are leveraging this advanced cooling approach to solve their heat dissipation challenges.

Data Centers and Cloud Computing

Data centers represent perhaps the most significant application area for two-phase cooling technology. The reasons are compelling:

Power Density Challenges

Modern server racks can generate heat exceeding 50kW per rack – far beyond what traditional air cooling can efficiently handle. Two-phase cooling solutions enable these high-density deployments without overheating.

Energy Efficiency Imperatives

With data centers consuming approximately 1-2% of global electricity, the energy efficiency improvements offered by two-phase cooling translate to significant environmental and financial benefits. Cloud computing cooling solutions are increasingly adopting these technologies.

Implementation Methods

Data centers typically implement two-phase cooling through:

- Immersion cooling: Servers are submerged in dielectric fluid that boils as it absorbs heat

- Two-phase cold plates: Direct contact with high-heat components while leveraging phase change

- Heat pipe-based cooling: Integrated into server design for efficient heat transport

Major cloud providers have reported up to 40% reduction in cooling energy costs after implementing two-phase cooling technologies.

AI and Machine Learning Infrastructure

The explosive growth of artificial intelligence has created unprecedented thermal management challenges:

GPU Cooling Requirements

Modern AI accelerators and GPUs can generate 400-700W of heat per card – often concentrated in small areas. Two-phase cooling is increasingly essential for these heat-intensive applications.

Performance Implications

AI workloads are particularly sensitive to thermal throttling, where performance is reduced to prevent overheating. Effective two-phase cooling maintains optimal operating temperatures, maximizing computational performance.

Scaling Challenges

Large language models require massive computing clusters, multiplying the cooling demands. Two-phase systems scale effectively to these requirements while maintaining energy efficiency.

According to Dr. Michael Chen, Research Director at the High-Performance Computing Institute, The advancement of AI would likely stall without corresponding advances in cooling technology. Two-phase cooling has emerged as the most promising solution for the thermal challenges posed by next-generation AI hardware.

Other High-Performance Computing Environments

Beyond data centers and AI, two-phase cooling is proving valuable across numerous high-performance computing applications:

- Scientific computing clusters: Supporting climate modeling, protein folding simulations, and other computation-intensive research

- Financial services: Enabling high-frequency trading systems where microseconds matter

- Oil and gas: Supporting seismic data processing and reservoir modeling

- Defense and aerospace: Cooling advanced radar systems and onboard computing

Industrial Applications

The benefits of two-phase cooling extend well beyond computing environments:

Power Electronics

IGBT cooling applications in power conversion systems benefit significantly from two-phase cooling. These high-power semiconductors generate substantial heat during operation, and two-phase cooling helps maintain optimal operating temperatures.

Electric Vehicles

EV battery cooling applications increasingly utilize two-phase cooling to manage battery temperatures during fast charging and high-performance driving. Proper thermal management is critical for battery longevity and safety.

Renewable Energy

Photovoltaic inverter heat sinks and other renewable energy components benefit from two-phase cooling to maintain efficiency in converting and transferring power, especially in high-temperature environments.

Telecommunications

5G telecom cooling applications use two-phase cooling to manage the increased heat generated by densely packed, high-frequency components in next-generation communication infrastructure.

Environmental Considerations and Sustainability

As thermal management technology advances, environmental impact becomes an increasingly important consideration. Two-phase cooling presents both challenges and opportunities from a sustainability perspective.

Current Environmental Challenges

Traditional two-phase cooling systems have faced legitimate environmental concerns:

Coolant Global Warming Potential

Some traditional refrigerants used in two-phase cooling have high global warming potential (GWP). For instance, older hydrofluorocarbon (HFC) coolants can have GWP values thousands of times higher than CO2.

End-of-Life Considerations

Proper disposal of specialized coolants remains challenging, requiring careful handling to prevent environmental contamination.

Manufacturing Impact

The production of specialized components for two-phase cooling systems can have a higher carbon footprint than simpler cooling technologies.

Newer, Eco-Friendlier Coolant Options

The industry has responded to environmental concerns with significant innovations:

Next-Generation Refrigerants

Newer coolants like R1233zd have dramatically lower GWP values (typically less than 5) while maintaining excellent thermal performance.

Natural Refrigerants

Some two-phase cooling systems now use natural refrigerants like:

- Carbon dioxide (CO2): GWP of 1 (by definition)

- Propane: GWP of approximately 3

- Ammonia: GWP of 0

Engineered Fluids

Specialized dielectric fluids with minimal environmental impact are being developed specifically for electronic cooling applications. These fluids combine good thermal properties with low GWP and zero ozone depletion potential.

Environmental scientist Dr. Sarah Johnson notes, The thermal management industry has made remarkable progress in developing eco-friendly coolants that don’t compromise on performance. This transformation has been crucial in making two-phase cooling a sustainable option for the future.

Lifecycle Assessment

When evaluating the environmental impact of two-phase cooling, a comprehensive lifecycle assessment reveals important insights:

Energy Savings

The operational energy efficiency of two-phase cooling often outweighs its production footprint. Over a typical 10-year lifespan, the reduced electricity consumption can represent a significant net environmental benefit.

Resource Conservation

By enabling higher computing density, two-phase cooling reduces the physical resources needed for data centers and other facilities, including construction materials, land use, and associated infrastructure.

Equipment Longevity

Better thermal management extends the useful life of electronic equipment, reducing electronic waste and the environmental impact of manufacturing replacement components.

Future Outlook

The environmental aspects of two-phase cooling continue to improve through:

- Closed-loop systems: Preventing coolant loss to the environment

- Recyclable components: Reducing end-of-life waste

- Manufacturing innovations: Lowering the carbon footprint of production

- Performance optimization: Enhancing efficiency to further reduce energy consumption

These ongoing improvements are making two-phase cooling not just a performance choice, but an environmentally responsible one as well.

Why Choose KenFaTech for Your Two-Phase Cooling Solutions

When it comes to implementing advanced thermal management technologies like two-phase cooling, choosing the right partner is crucial. KenFaTech stands out as a leader in this specialized field for several compelling reasons.

Industry Expertise and Experience

With over a decade of experience in thermal management solutions, KenFaTech brings unparalleled expertise to every project:

Specialized Knowledge

KenFaTech’s engineering team includes thermal specialists formerly from renowned companies like AAVID and Foxconn. This collective experience ensures solutions that incorporate industry best practices and cutting-edge innovations.

Comprehensive Approach

From initial thermal design and management to final implementation, KenFaTech offers end-to-end expertise that covers every aspect of thermal solutions. This holistic perspective ensures all components work together seamlessly.

Proven Track Record

KenFaTech has successfully implemented thermal management solutions across diverse industries, including telecommunications, data centers, electric vehicles, and renewable energy. This broad experience translates to adaptable solutions that meet specific industry requirements.

Customization Capabilities

Every cooling challenge is unique, which is why KenFaTech emphasizes customization in all its solutions:

Tailored Design Process

KenFaTech’s approach begins with understanding your specific requirements, constraints, and performance goals. This client-centered process ensures solutions that precisely match your needs rather than one-size-fits-all approaches.

Advanced Simulation Tools

Using sophisticated thermal analysis tools like Ansys Icepak and Flotherm, KenFaTech can accurately predict thermal performance before manufacturing begins. This capability reduces development time and ensures optimal results.

Manufacturing Flexibility

KenFaTech offers multiple manufacturing processes including:

- Extrusion process for efficient heat sink production

- Skived fin process for high-performance applications

- Bonded fin process for complex geometries

- Cold forged process for superior thermal performance

- Brazing process for creating reliable liquid cooling solutions

This manufacturing versatility allows KenFaTech to select the optimal fabrication method for each specific application.

Quality Assurance Processes

KenFaTech maintains rigorous quality standards throughout design and manufacturing:

Comprehensive Certifications

With certifications including ISO9001:2008, ISO14001:2004, and IATS16949, KenFaTech adheres to international quality standards across all operations.

Extensive Testing

KenFaTech’s testing and validating processes ensure every product meets performance specifications before delivery. This includes thermal performance testing, pressure testing for liquid systems, and accelerated life testing when appropriate.

Quality Control

Rigorous QC quality control procedures at every stage of manufacturing ensure consistency and reliability in all KenFaTech products.

Customer Success Focus

Beyond technical excellence, KenFaTech prioritizes customer satisfaction through:

Collaborative Partnership

KenFaTech works closely with clients throughout the development process, ensuring open communication and alignment with project goals.

Responsive Support

Technical support doesn’t end with product delivery. KenFaTech provides ongoing assistance to ensure optimal performance of their thermal solutions.

Cost-Effective Solutions

While never compromising on quality, KenFaTech strives to deliver solutions that provide excellent value and return on investment. This balance of performance and affordability has made KenFaTech a trusted partner for companies worldwide.

Dr. Robert Zhang, Thermal Engineering Director at KenFaTech, explains, Our approach to two-phase cooling is grounded in both theoretical excellence and practical implementation. We don’t just design for ideal conditions but for the real-world challenges our clients face daily. This pragmatic perspective is what distinguishes KenFaTech in the thermal management industry.

Frequently Asked Questions About Two-Phase Cooling

As two-phase cooling technology gains prominence, many questions arise about its implementation, benefits, and limitations. Here, we address the most common inquiries to help you better understand this advanced cooling approach.

General Questions

What is the difference between two-phase and single-phase cooling?

Two-phase cooling involves a phase change from liquid to vapor, enhancing heat transfer efficiency through the latent heat of vaporization. Single-phase cooling relies solely on the sensible heat capacity of the coolant, which remains in one

What is the difference between two-phase and single-phase cooling?

Two-phase cooling involves a phase change from liquid to vapor, enhancing heat transfer efficiency through the latent heat of vaporization. Single-phase cooling relies solely on the sensible heat capacity of the coolant, which remains in one state throughout the cooling process. This fundamental difference is why two-phase cooling can be 5-10 times more efficient at removing heat.

Is two-phase cooling more efficient than air cooling?

Yes, two-phase cooling is significantly more efficient than air cooling, especially in high-density applications. Air has a very low heat capacity compared to liquids, and two-phase cooling adds the benefit of phase change energy absorption. Practically speaking, while air cooling typically struggles beyond 150 W/cm², two-phase cooling can efficiently handle heat fluxes exceeding 1000 W/cm² in optimal configurations.

What types of coolants are used in two-phase cooling systems?

Two-phase cooling systems use various coolants depending on the specific application requirements:

- Dielectric fluids: These non-conductive fluids are safe for direct contact with electronics and include engineered fluids like Novec and Fluorinert.

- Refrigerants: Modern options include R1233zd and other low-GWP alternatives.

- Natural refrigerants: Including CO2, propane, and in some specialized applications, ammonia.

- Water: Used in closed systems like heat pipes where there’s no direct contact with electronics.

The selection of coolant for liquid cooling systems depends on factors including thermal properties, environmental impact, safety, and compatibility with system materials.

Implementation Questions for two-phase cooling

How does two-phase cooling reduce energy consumption?

Two-phase cooling reduces energy consumption through several mechanisms:

- Natural convection: Vapor rises naturally due to buoyancy, requiring less pumping energy.

- Efficient heat transfer: Phase change provides much more cooling per unit of fluid moved.

- Reduced peripheral equipment: Less need for fans, large pumps, and other energy-consuming components.

- Lower coolant volume: Less fluid needs to be circulated to achieve the same cooling effect.

These factors combine to significantly reduce the energy parasitic load of cooling systems, which can account for 30-50% of total energy consumption in traditional data centers.

What are the maintenance requirements for two-phase cooling systems?

Maintenance requirements vary by system type:

- Passive systems (heat pipes, vapor chambers): Virtually maintenance-free with no moving parts to wear out.

- Immersion cooling: Occasional coolant top-off and periodic filtration to remove particulates.

- Two-phase cold plates: Similar maintenance to liquid cooling systems with periodic checks for leaks and proper operation.

Overall, two-phase cooling systems typically require less maintenance than traditional air or single-phase liquid cooling, contributing to their lower total cost of ownership.

Can two-phase cooling be retrofitted to existing systems?

Retrofitting possibilities depend on the specific application and system architecture:

- Heat pipe and vapor chamber solutions: Often can be retrofitted into existing designs as enhanced heat spreaders.

- Immersion cooling: Generally requires significant modification to existing infrastructure.

- Two-phase cold plates: May be retrofitted if the system already uses liquid cooling infrastructure.

KenFaTech offers consultation services to evaluate retrofitting options for specific applications, ensuring the most cost-effective approach to implementing two-phase cooling in existing systems.

Technical Questions

What are the temperature limits of two-phase cooling systems?

Temperature limits depend primarily on the coolant used and system design:

- Most electronic cooling applications operate in the 20-100°C range.

- Specialized high-temperature two-phase systems can operate at 150°C or higher.

- Low-temperature applications can reach temperatures below -40°C with appropriate refrigerants.

The ability to customize operating temperatures by selecting appropriate working fluids is one of the key advantages of two-phase cooling systems.

How does pressure affect two-phase cooling performance?

Pressure directly influences the boiling point of the coolant, which is central to two-phase cooling operation:

- Higher pressure raises the boiling point, which can be desirable for higher temperature operation.

- Lower pressure reduces the boiling point, enabling phase change at lower temperatures.

- Pressure control is often used to optimize system performance across varying heat loads.

Proper pressure management is essential for efficient and reliable two-phase cooling system operation.

What are the safety considerations for two-phase cooling systems?

Safety considerations include:

- Pressure containment: Systems must safely manage the pressure of vaporized coolant.

- Coolant properties: Some refrigerants require specific handling procedures and ventilation.

- Electrical isolation: For immersion systems, ensuring proper electrical isolation and grounding.

- Leak prevention: Especially important for systems using non-dielectric coolants.

KenFaTech designs all its two-phase cooling solutions with comprehensive safety considerations that meet or exceed industry standards.

Conclusion: The Future of Cooling Technology

As we look toward the future of thermal management, two-phase cooling stands out as a pivotal technology that will continue to evolve and expand in significance. Let’s explore the trajectory of this innovative cooling approach and what it means for the industry.

Emerging Industry Trends

Several key trends are shaping the future of two-phase cooling:

Increasing Adoption

Two-phase cooling is rapidly transitioning from a specialized technology to a mainstream solution, particularly in data centers and high-performance computing environments. As power densities continue to rise with each new generation of processors and accelerators, two-phase cooling is becoming less of a luxury and more of a necessity.

Environmental Focus

The development of environmentally friendly refrigerants and coolants is accelerating, driven by both regulatory pressure and corporate sustainability initiatives. This evolution is removing one of the historical barriers to widespread adoption of two-phase cooling.

Standardization Efforts

Industry consortiums are working to establish standards for two-phase cooling implementations, which will help reduce costs and improve interoperability between systems from different manufacturers.

Integration with AI for Optimization

Artificial intelligence is increasingly being used to optimize cooling system operation in real-time, predicting heat loads and adjusting system parameters for maximum efficiency. This integration of AI with two-phase cooling creates a powerful synergy for next-generation thermal management.

KenFaTech’s Position in the Evolving Landscape

As a pioneer in thermal management solutions, KenFaTech is well-positioned to lead in this evolving landscape:

Innovation Leadership

KenFaTech continues to invest in research and development focused on advanced two-phase cooling technologies, ensuring our solutions remain at the cutting edge of thermal management.

Sustainability Commitment

Our focus on environmentally responsible cooling solutions aligns with the industry’s trajectory toward more sustainable thermal management approaches. KenFaTech is committed to developing and implementing eco-friendly cooling technologies.

Collaborative Approach

Through partnerships with technology leaders and participation in industry standardization efforts, KenFaTech is helping shape the future of thermal management while ensuring our solutions maintain compatibility with evolving industry standards.

Call to Action

The thermal management challenges of tomorrow require innovative solutions today. As computing demands continue to increase exponentially, staying ahead of thermal management requirements is essential for maintaining competitive advantage and operational efficiency.

KenFaTech invites you to explore how our advanced two-phase cooling solutions can address your specific thermal management needs:

- Consult with our experts: Our thermal engineers can assess your current cooling challenges and recommend optimized solutions tailored to your requirements.

- Explore our portfolio: Review our range of thermal management products, including those leveraging two-phase cooling technology.

- Request a custom solution: If your thermal challenges require a unique approach, KenFaTech’s design team can develop a customized solution specifically for your application.

Don’t let thermal limitations constrain your technological ambitions. Contact KenFaTech today to discover how our advanced cooling solutions, including cutting-edge two-phase technologies, can help you overcome your most challenging thermal management obstacles and unlock new possibilities for your systems.

Remember: In the world of high-performance computing and electronics, effective cooling isn’t just about preventing failures—it’s about enabling opportunities for innovation, efficiency, and competitive advantage.

External Resources

For those interested in learning more about two-phase cooling technologies and applications, here are some valuable external resources:

- Electronics Cooling: Two-Phase Immersion Cooling for Power Electronics Applications

- Data Center Knowledge: Immersion Cooling and Data Centers: A Perfect Match

- ASHRAE: Liquid Cooling Guidelines for Datacom Equipment Centers

- Science Direct: Heat Transfer Analysis in Two-Phase Cooling Systems

- U.S. Department of Energy: Liquid Cooling Technologies for Data Centers

These resources provide additional context and technical depth on the principles, applications, and benefits of two-phase cooling technologies across various industries.