Liquid Cold Plate are a common type of heat dissipation device that is widely used in electronics and computers. It is a solution to reduce the temperature of equipment through water cooling technology. Compared with traditional air-cooled Heat Sink, Liquid Cold Plate are highly sought after for their higher cooling efficiency and lower noise levels. In this article, we will introduce the principle, structure, working mode and advantages of Liquid Cold Plates in detail, providing you with a comprehensive explanation of Liquid Cold Plates.

Liquid Cold Plate working principle

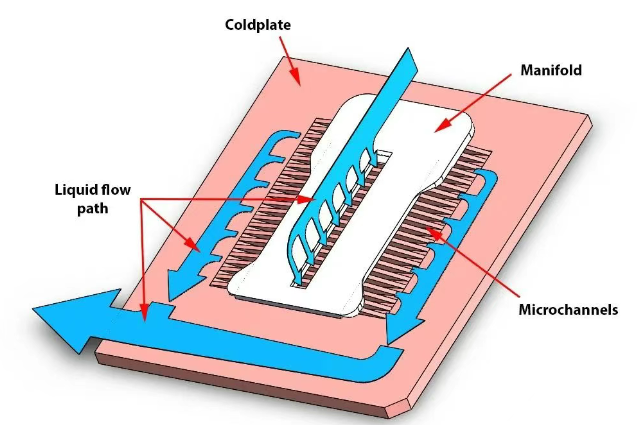

First, let’s understand the principle of liquid cooling plates. A liquid cooling plates reduces the temperature of the equipment by transferring heat through the water stream. It uses a thermally conductive material, usually thermally conductive copper or aluminum, to transfer heat from the equipment to the water stream. This removes the heat quickly and keeps the equipment running at a lower temperature. Liquid Cold Plate are usually used in conjunction with a water-cooled cooling system that includes components such as pumps, tanks, cooling fans and condensers.

The structure of a Liquid Cold Plate usually consists of a chip and a cooling module. The chip is the core component of the device that generates heat, such as the central processing unit (CPU) or graphics card (GPU). The heat sink module is located above the chip and is in direct contact with the chip to ensure rapid heat transfer. The heat sink module usually consists of a thermally conductive material and a heat sink, which is fitted with cooling fins to increase the heat dissipation area and improve the heat dissipation efficiency.

Liquid Cold Plate work in a complex way and need to work together with other components of the water cooling cooling system. First, a pump draws the coolant (usually water) out of the tank and through the chip portion of the cooling plate, where it touches the surface of the chip through a thermally conductive material that absorbs the heat. The heat is then quickly carried away by the conduction of the coolant. The coolant flows through the condenser, where it dissipates the heat and releases it to the outside environment. Finally, the coolant is returned to the water tank and runs in a cycle, continuously lowering the temperature of the equipment.

Advantages of liquid cooling plates

liquid cooling plates have a number of advantages that make them ideal for use in electronics and computers. First, the cooling efficiency of Liquid Cold Plate far exceeds that of traditional air-cooled Heat Sink. Because water has better thermal conductivity, it absorbs and conducts heat faster, thus lowering device temperatures more effectively. This is especially important for devices that process large amounts of data, perform complex calculations, or run high-performance applications to improve stability and performance.

Second, liquid cooling plates operate at a lower noise level. Traditional air-cooled Heat Sink require the use of a fan to exhaust hot air, which tends to generate noise. liquid cooling plates, on the other hand, are much quieter as they use a water-cooled cooling system that removes heat from the unit and dissipates it through natural convection or additional cooling fans as the coolant passes through the condenser.

Once again, Liquid Cold Plate have advantages in terms of cooling capacity and flexibility. Since liquid cooling plates use water cooling technology, they can be customized to meet the cooling needs of different devices. For high-performance equipment, the number or size of cooling modules can be increased and the operating parameters of the water-cooled cooling system can be adjusted according to demand. This can better meet the cooling needs of different devices and provide the best cooling effect.

In addition, Liquid Cold Plate offer better reliability and stability. As water cooling cooling systems provide better control of the temperature of the equipment, the operating temperature fluctuation of the equipment is reduced, which in turn reduces the failure rate of the equipment. This is especially important for high-load equipment such as servers, supercomputers and gaming devices that run for long periods of time, improving the stability and longevity of the equipment.

How do you tell the pros and cons of liquid cooling plates designs?

Look at the material.

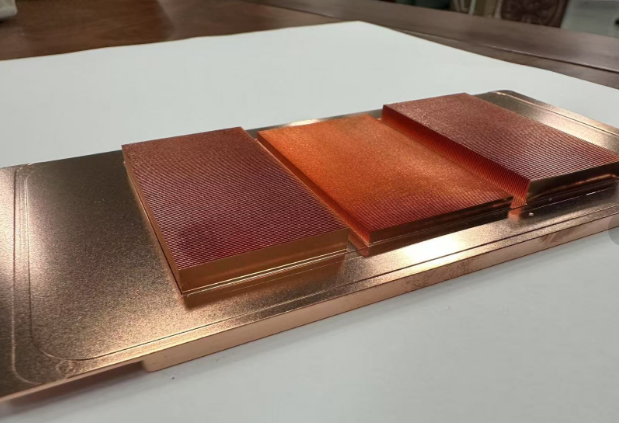

Liquid Cold Plate of the main materials for copper, aluminum, aluminum is silver-white, easy to extend, tough and light, good electrical and thermal conductivity, copper rich in ductility, is a good conductor of heat and electricity, the surface of the wet air to generate copper-green, can be made of a variety of alloys (eg, brass, copper alloy) and electrician’s equipment.

The use of aluminum and copper alloys are cost-effective and relatively low cost. For this reason most water-cooled Heat Sink on the market are designed with aluminum panels buried in copper tubes. The quality of the cold plate material can be distinguished by looking at the quality of the aluminum and copper and the absence of impurities, i.e. the quality of the raw material.

Judge by the workmanship

For the manufacture of Liquid Cold Plate the materials can be the same but the production process is different, resulting in completely different Heat Sink. The process must start in two ways.

On the one hand, whether the production is carried out according to the design drawings. The indicated parameters are checked using vernier calipers. Errors within 0.05 millimeters can be considered qualified, while high requirements can result in an accuracy of up to 0.02 millimeters.

liquid cooling plates workmanship angle

The process of embedding the aluminum plate through the copper tube can cause adhesion problems. If there is a gap between the two, it will affect the heat dissipation effect and even cause water leakage. Condition. In addition, the copper tube and aluminum plate are connected through the embedded tube process, and then processed through the polishing or flying surface process, so that the whole Liquid Cold Plate forms a flat surface, from which the quality can also be observed. Leveling, whether the copper tube and aluminum plate are fused into a plane, gap or unevenness will affect the cooling effect.

Performance testing

With a few aspects, you can roughly determine the advantages and disadvantages of a radiator water cooling panel. If it is more demanding, you can ask Kenfa-Tech for the measurement data of heat dissipation.

It is more accurate to judge by the data. When the Liquid Cold Plate product is finished, the Liquid Cold Plate supplier will carry out various performance tests on the Liquid Cold Plate product, focusing on the heat dissipation performance of the radiator and the reliability of the performance must be up to the level specified in the standard.

The reliability of the radiator includes radiator sealing performance, vibration resistance, pressure cycling performance, resistance to high temperature pressure pulse performance, the thermal performance of the radiator includes the radiator pressure level, temperature level, heat dissipation structure, heat dissipation tube wall thickness and other conditional factors, which plays a decisive role in the overall performance of the radiator. The data becomes one of the external references to visually judge the advantages and disadvantages of the product, which is highly efficient and credible.

Misconceptions about liquid cooling plates

Liquid Cold Plate is a widely used technology for cooling computer hardware, which has become more and more popular among users in recent years. However, due to limited knowledge of Liquid Cold Plates, many people have some misconceptions. The following aims to analyze these misconceptions, help readers better understand Liquid Cold Plates, and provide detailed solutions and tips.

Myth 1: The higher the Liquid Cold Plate power, the better

Many people think that one of the main hallmarks of a water cooler is power, and that higher power means better cooling performance. However, the reality is not so simple. The power of a water cooler is not directly related to its actual cooling capacity. When choosing a water cooler, factors such as cooling performance, noise and power consumption should be taken into account. Higher power Cold Plate may show better performance, but they also produce more noise and consume more power. Therefore, users should choose the right water cooler according to their needs and actual situation, not just limited to the power level.

Myth 2: Liquid Cold Plate must be better than air-cooled boards

liquid cooling plates have a clear advantage in thermal performance over traditional air-cooled panels. However, this does not necessarily mean that Liquid Cold Plates are better than air cooling boards. Liquid Cold Plate do show better performance for some specific scenarios and needs, such as overclocking and gaming and other high-intensity tasks. However, for the average user, air-cooled boards are sufficient for daily use. In addition, Liquid Cold Plates are relatively complicated to install and maintain, requiring additional costs and operations, so you need to weigh the pros and cons when choosing one.

Myth 3: Water coolers must match the graphics card

Some users associate Liquid Cold Plates with the model of the graphics card, believing that only certain cards are suitable for water cooling. In fact, Liquid Cold Plates are not limited to a specific model of video card. Most Cold Plate are universal and can be used with a wide range of graphics cards. However, different cards may require different adapters or cooling blocks, which may require some hardware modifications. Therefore, when purchasing a Liquid Cold Plate, you need to be aware of the availability of ports or adapters that are compatible with your own graphics card.

Myth 4: liquid cooling plates require frequent maintenance

Some people think that Cold Plate need frequent maintenance or they will fail. The truth is that Cold Plate, like other cooling methods, do not require frequent maintenance. If Cold Plate are properly designed, they will last for several years. Just be sure to keep the water clean and check the cooling system regularly to make sure it is working properly. If there is a problem, it is usually a leakage of cooling liquid or a broken pump, which can be maintained and repaired according to the service manual.

Myth 5: Cold Plate Must Leak

Some people are concerned that the use of Liquid Cold Plates may cause leakage and hardware damage. In fact, well-designed and properly used liquid cooling plates are not prone to leakage. Modern liquid cooling plates adopt many leakage prevention measures, such as leakage prevention fittings, safety valves and other equipment, which can effectively reduce the risk of leakage. At the same time, users should strictly follow the instructions during installation and use to avoid leakage caused by improper operation.

Conclusion

liquid cooling plates are a highly efficient, low-noise heat dissipation method, but there are some common misconceptions. Users in the selection and use of Liquid Cold Plate should fully understand its characteristics and application, to avoid being misled by some inaccurate or one-sided concepts, it is best to choose the regular Liquid Cold Platemanufacturers and radiator manufacturers of products, quality and after-sales service will be more guaranteed. We hope that the above detailed explanation and suggestions can help users better understand and use liquid cooling plates.