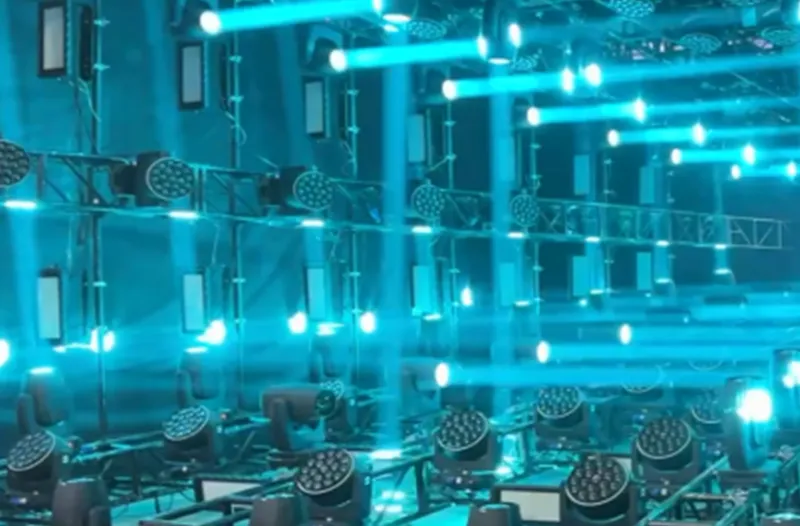

Cooling Solution for LED Lighting Industry

The heat dissipation scheme of the LED lighting industry generally uses natural convection or forced convection scheme. Of course, the heat dissipation scheme is different from the customer's lamp type

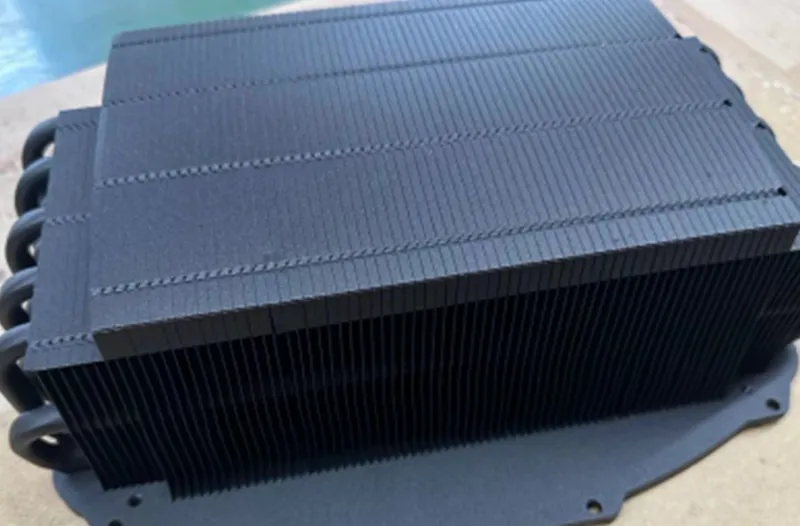

Heat pipe assembly of the heat sink, due to the 600W LED stage light heat management solution.

The importance of heat pipe assembly heat sink for cooling stage lights

The importance of heat pipe heat sinks for stage lights cannot be underestimated, especially for high-power and high-brightness stage lighting equipment. Stage lights often require high electrical power to produce intense lighting effects, resulting in the generation of substantial heat. The performance of stage lights is closely related to the temperature of the light-emitting components. Elevated temperatures can reduce the efficiency of these components, leading to diminished brightness or color distortion, thereby affecting the overall lighting effects. Heat pipe heat sinks help maintain the stage lighting equipment within an optimal temperature range, ensuring stable and reliable lighting performance.

How to make this 600W heat pipe assembly heat sink?

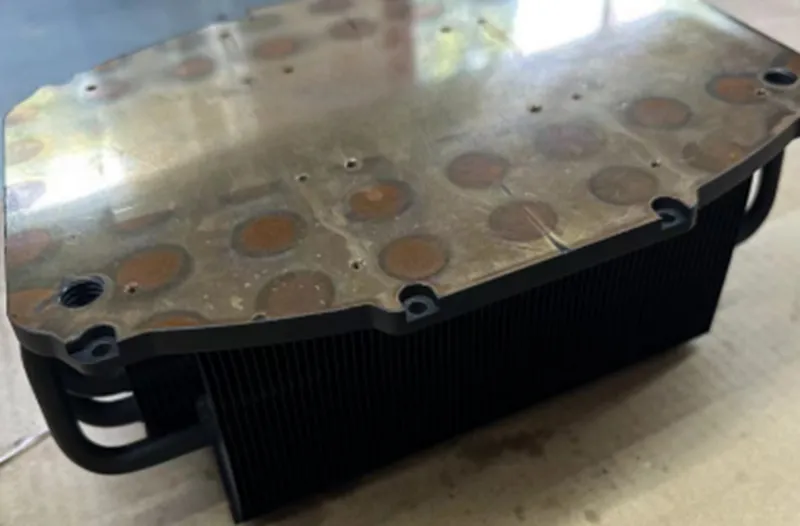

our engineers calculated the required heat sink area based on the heating power of the stage lights.After thermal analysis, it was found that the size of the heat sink to solve the heat of 600W is very large.To solve this limited size range of heat, engineers used heat pipe process heat sinks.The bottom of the heat sink is made of copper, which is conducive to the transmission of heat.In order to increase the heat dissipation area of the heat sink, the engineers used a high-density stamping fin with a thickness of 0.4mm.In order to connect the heat pipe and fin closely, the surface is plated with nickel and soldered with solder paste, which ensures that the two parts are in close contact with good thermal conductivity and very low thermal resistance.

Based on the 600W of heat, we used 12 heat pipes to transfer heat, and each heat pipe took away 55-60W of heat.The temperature of the working environment of the heat pipe is set to minus 30 degrees to 105 degrees, which is the highest efficiency. Of course, considering the gravity effect of the stage lamp in the actual application, we especially control the capillary structure of the heat pipe and the water injection of the liquid. This gravity treatment method makes the stage lamp in different Angle applications, It will not fail because of the gravity of the heat pipe.

How to deal with the surface treatment of heat pipe assembly heat sink?

Generally speaking, the use of stage lights is more common in indoor and outdoor, so the waterproof treatment of stage lights is very important.As we have mentioned before, our engineers design this heat sink using the process of surface nickel plating and soldering paste welding. When water is encountered, the nickel plated fins will be oxidized and corroded, so we must do anti-oxidation and corrosion treatment on the fins.Surface dusting and oil spraying are commonly used.

The surface powder spraying treatment is generally made of fluorocarbons made of carbon nanomaterials. This material has very strong corrosion resistance. At the same time, due to the properties of nano, its thermal radiation value is very high (greater than 0.8, the theoretical value is 1.0).

The benefit of this treatment is that the corrosion and oxidation resistance are very good due to the strong adhesion of oil molecules. Because it is a soldering paste welding process, usually the welding temperature is 150 degrees, so we in the powder and oil injection, the temperature control is very accurate, generally is about 110 degrees, to complete the baking for 1 hour, especially the radiator pretreatment, oil removal and other processes are also very important. This process directly affects the adhesion effect of the spray powder behind. Of course, we will do the quality test, this standard is usually called the hundredfold test.

What are our considerations for the heat sink in the design of the stage light?

- Are you using Forced Convection for cooling your LED?

- Do you think about noise? What about fan specifications?

- Will you need use heat pipes assembly for the heat sink?

- What is the maximum ambient temperature that your LED will be operating in?

- How much power is your LED light dissipating?

- What is your maximum device case temperature?

- What is your LED or PCB size and heat source footprint?

- How much room do you have for your heat sink?

- Is there a weight requirement and cost budget?

Do you need to find an expert in thermal design and production?

As a professional manufacturer of heat sink production and design, we have more than 10 years of production experience, we can provide you with system-level heat sink design and comprehensive service. It is aslo a good helper for your products to market quickly.If you want to know more about the details of this 600W heat sink , you can contact us by email. Our engineer will discuss with you in detail whether it can be applied to your LED lighting or chipsets.