5G Telecom cooling applications

With the development of 5G communication technology, more and more attention has been paid to the corresponding cooling system requirements.For the stable operation of the equipment

5G Telecom Thermal Management.

The thermal management system of 5G communication is a key technology used to effectively manage the heat generated during high-frequency and high-speed data transmission. The system adopts advanced heat dissipation technology, including thermal conductive materials, heat sinks, and fans, to ensure that the equipment maintains a suitable temperature during high load operation.

At the same time, intelligent temperature control algorithms are applied to real-time monitoring of device temperature and automatically adjusting the operating status of the cooling system according to the situation, ensuring that the equipment operates within a safe range. In addition, the system also adopts energy-saving design, optimizes power distribution, reduces power consumption, and reduces heat generation. Through these thermal management strategies, 5G communication devices can achieve efficient and stable operation, improve system performance, extend device lifespan, and ensure user experience and reliability of communication networks. how to design a telecom station heat sink?

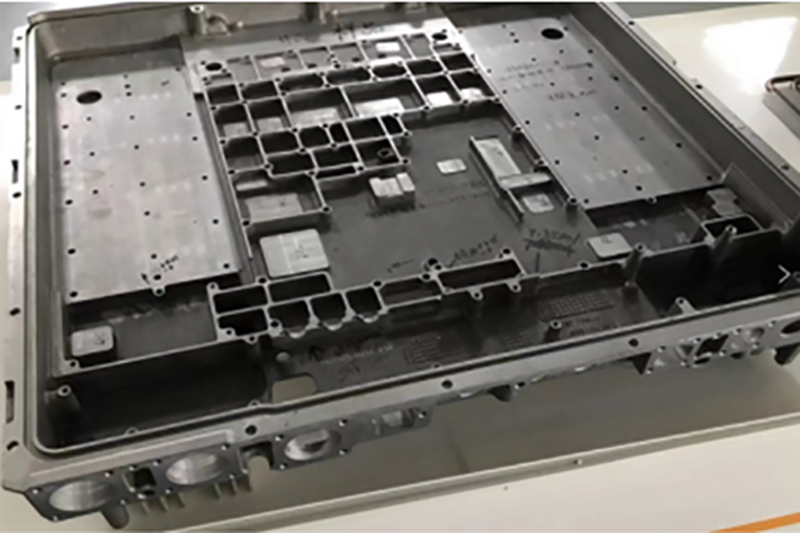

5G Telecom Heat Sink Process

Die casting heat sink technology plays a crucial role in 5G communication heat dissipation. Through die casting technology, metal heat sinks with excellent thermal conductivity can be manufactured for effective heat dissipation of 5G equipment. The die-casting process can achieve complex structures, ensuring that the shape and size of the radiator accurately meet design requirements. Aluminum alloys and other metals with high thermal conductivity are widely used to ensure rapid heat conduction. Die casting also provides a highly controllable production process to ensure consistent quality of mass-produced heat sinks, meeting the strict requirements of 5G communication equipment for efficient heat dissipation. Heat pipe can also be added in local areas to improve heat dissipation efficiency.

Liquid cooling plate technology is an innovative means of 5G communication heat dissipation. By introducing cooling liquid, the heat generated by the equipment is quickly absorbed, achieving efficient heat dissipation. Compared with traditional heat dissipation methods, liquid cooling technology can distribute heat more evenly, improve heat dissipation efficiency, ensure the stability of equipment during long-term high load operation, and reduce noise and energy consumption, providing critical support for the reliability and performance of 5G equipment.

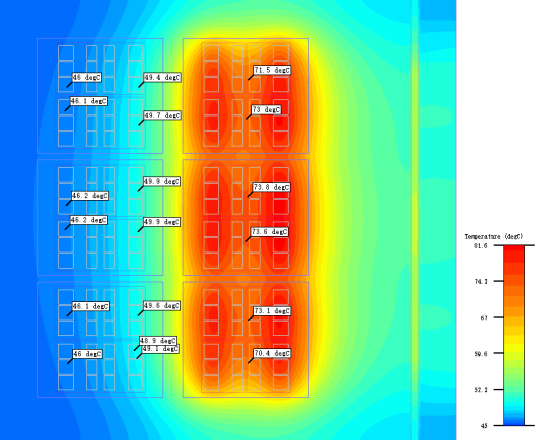

Thermal Analysis Design For 5G Telecom Heat Sink

We have excellent capabilities to provide customers with high-quality 5G communication heat sinks. Firstly, we have advanced heat dissipation technology and manufacturing processes, including liquid cooling technology and die-casting technology, to ensure excellent performance of the heat sink in high-frequency and high load 5G communication environments. Our team is composed of experienced professionals who can thermal design and manufacture efficient cooling solutions to meet the specific needs of our customers.

In addition, we pay attention to material selection and use high thermal conductivity materials such as aluminum alloy to ensure that the heat sink quickly conducts and dissipates heat in a short period of time. We are committed to quality control, ensuring the reliability and stability of each heat sink through strict performance testing and inspection procedures. In the end, we provide customers with 5G communication cooling solutions that meet the latest technological standards with the concept of environmental protection and sustainability. By choosing us, you will receive top-notch products and services that meet the excellent heat dissipation performance requirements of 5G communication devices.

Quality Control of Kenfa's 5G Telecom Heat Sink

Quality control is crucial when producing 5G communication heat sinks. Firstly, ensure that the quality of raw materials meets the standards and use materials with high thermal conductivity, such as high-quality metals and heat dissipation adhesives. Secondly, establish a precise production process, implement strict manufacturing standards, and ensure that the manufacturing process of each heat sink complies with design specifications.

Adopting automated equipment and advanced production technology to improve production efficiency while reducing human error. During the production process, regular quality inspections and sampling inspections are carried out to ensure that the products meet the design requirements. Finally, establish a comprehensive after-sales service and traceability system to track and improve potential issues, in order to ensure the long-term stability of the product and customer satisfaction. Through these control measures, it can be ensured that the 5G communication heat sink maintains high quality during the production process and meets market demand.

Why to Choose Kenfa's 5G Telecom Heat Sink

We have outstanding capabilities in design, processing, quality control, and delivery time. We have a strong design team focused on innovative cooling solutions to meet different needs. Advanced processing equipment and technology ensure precise manufacturing of products, ensuring excellent performance.

In terms of quality control, we implement strict production standards and quality inspection processes to ensure that each 5G telecom heat sink or liquid cold plate meets high standard requirements. At the same time, we focus on delivery time management, efficient production organization, and supply chain advantages to ensure timely delivery and meet urgent customer needs. Overall, our comprehensive strength in design, processing, quality control, and delivery time management is the core reason why customers trust us.