Case Studies-115W TEC heat sink thermal solution

We will use professional thermal analysis software to design the optimal scheme for customers, then confirm the

feasibility of the theory with engineers, and then start to make samples for testing

115W TEC heat sink thermal solution

Project Details

Customer:

Medical manufacturer

Application:

Medical equipmentindustry

Technology:

Liquid cold plate

Thermal power type:

TEC cooling

Location:

US

Intruduction

As a special field in the medical industry, the precision of electronic components is very important, so the heat sink of components is very important, even a key component. In particular, for the TEC refrigeration program, both extremely cold and extremely hot will have an impact on the equipment, especially the phenomenon of ice accumulation or water accumulation at low temperature. Therefore, our engineers carefully and seriously consider these problems when designing such projects.

The Thermal Solution

Designed requirements

Power 100+15=115W

Al1060 Skived fin +Heat pipes

Input flow Fan9238(2.81M3/Min)*1pcs

Environment 45℃

Simplified model and heat source in Pro/E

Parameter setting and meshing are in the software,The number of meshes is 418847 Set uniform mesh params ,Mesh assemblies separately,Allow multi-level meshing,Allow minimum gap changes

To solve the function calculation equation, make each curve function equation convergent based on the set parameters

After the software is run, the air volume pressure is obtained, so as to determine a reference value for the fan resistance impedance in the later period.Orient positive X,Y,Z Temperatures

Also, after the software is run, the speed of the air volume is obtained, so as to determine a reference value for the later fan air volume

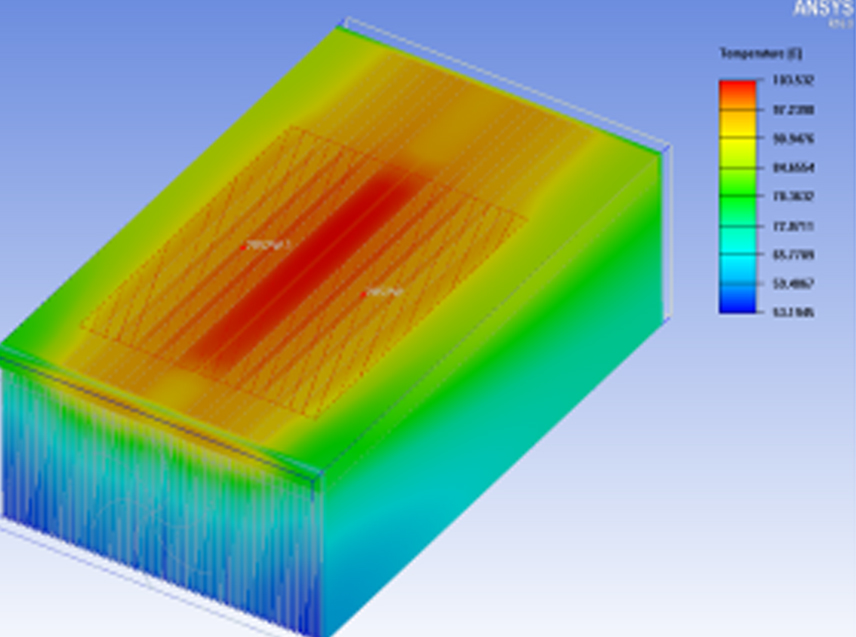

After calculation, the temperature distribution diagram of the heat source within the range of the set module is obtained, and then the engineer can optimize it.

Finally, we designed the scheme, and then made samples for our customers to test, and the results showed that they fully met their needs.

Results

Our engineers use detailed data and accurate meshing CFD software for calculation. By constantly adjusting the data module, heat pipe position, and thickness and spacing of heat sinks fins, we finally designed a heat sink scheme meeting the requirements for the customer. Meanwhile, we have made sample testing and mass production. However, the heat pipe heat sink should be noted that in extreme environment, the liquid inside the heat pipe is easy to freeze and then expand. Used the simple model method, the result will be different from the actual module. The Max temperature of Al block surface is below 29.6℃,△T=64.8-40=24.8 ℃