Kenfa's liquid cold plate for 280Ah battery cells cooling

Our company provides a universal and standardized liquid cooling plate for customers to cool battery modules with different currents, reducing sample development design and costs

105181110 liquid cold plate for 280Ah battery cells cooling

After more than 10 years of production experience, we have found that the battery modules of our customers are quite universal. Therefore, we have designed and produced a liquid cooling plate that can cool the battery modules according to the commonly used battery module sizes in the market.We use Extrusion technology to make microchannels for liquid cooled plates, which can save the cost of CNC machining channels or the cost of using copper tubes as channels.Then, the front and rear ends are welded together using Friction Stir Welding to form a closed M-shaped flow channel.

For the entire battery cells, some components can be welded onto the cold plate for fixing and installing the battery module. At this time, we can use argon fluorine welding to complete the process.So, our system level battery thermal management solution can provide customers with a lot of convenient services and design experience.

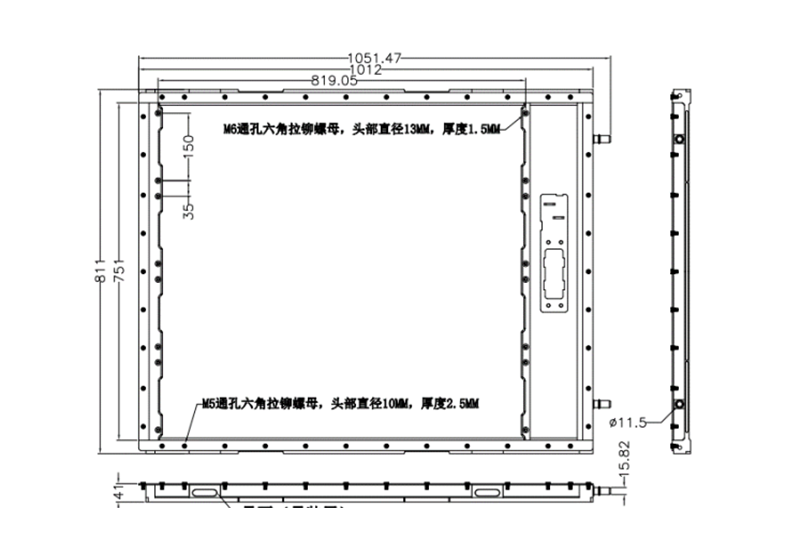

Parameters of cold plate

-Material:AL6063-T5

-Size:1051mmx811mmx10mm

-The diameter of the inlet and outlet is 18mm, which can be matched with standard connectors;

-Finshing-Spray insulation paint for the cold plate

1,Black color;

2,250+-50um (0.2-0.3mm);

3, voltage>=2500VDC@10S;

4, Relative humidity<=90%;

5, insulation value>=500MΩ;

6, Dielectric Strength >=3820VDC@60S;

7, Leakage current value<=10mA;

Thermal design for liquid cold plate

The design of this battery consists of 48 battery cells in series, followed by 1 parallel connection, with a maximum current of 280Ah. It belongs to a type of energy storage and power battery. When the maximum charge is reached, the released thermal power consumption is 520W. At this point, our cold plate starts working, and a flow rate of 4.5L/min can control the temperature of the entire cold plate below 25 degrees Celsius. The temperature of the entire module is very uniform.

So, this preliminary theoretical data thermal simulation analysis can have a very clear understanding of the entire battery thermal management, providing reliable assurance for subsequent current design and theoretical basis.

What else can we do for our customer?

Our standard liquid cooling plate can be modified by customers without changing the width of the product, that is, without changing the size of 776mm. Of course, the thickness of 10mm cannot be modified, as it is a profile mold. Therefore, we can change the diameter and position of the inlet and outlet, and the length of the entire liquid cooling plate can be modified. Different parts with different characteristics are welded on the cold plate to fix and install other accessories. In short, Our experience can save customers a lot of start time and costs, and we are also your trusted partner.